In today’s competitive business environment, maximizing efficiency while minimizing waste is more important than ever. This is where the 5S methodology comes into play. Rooted in the principles of lean manufacturing, the 5S methodology provides a clear and practical framework for organizing workspaces, improving productivity, and ensuring safety. Whether you run a manufacturing plant, a healthcare facility, or an office, the 5S methodology can transform your work environment for the better.

In this guide, we will delve into what the 5S methodology is, explore its benefits, and provide a step-by-step guide on how to implement it. We will also cover real-world applications, discuss common challenges, and offer tools that can help sustain the system over time.

What Is the 5S Methodology?

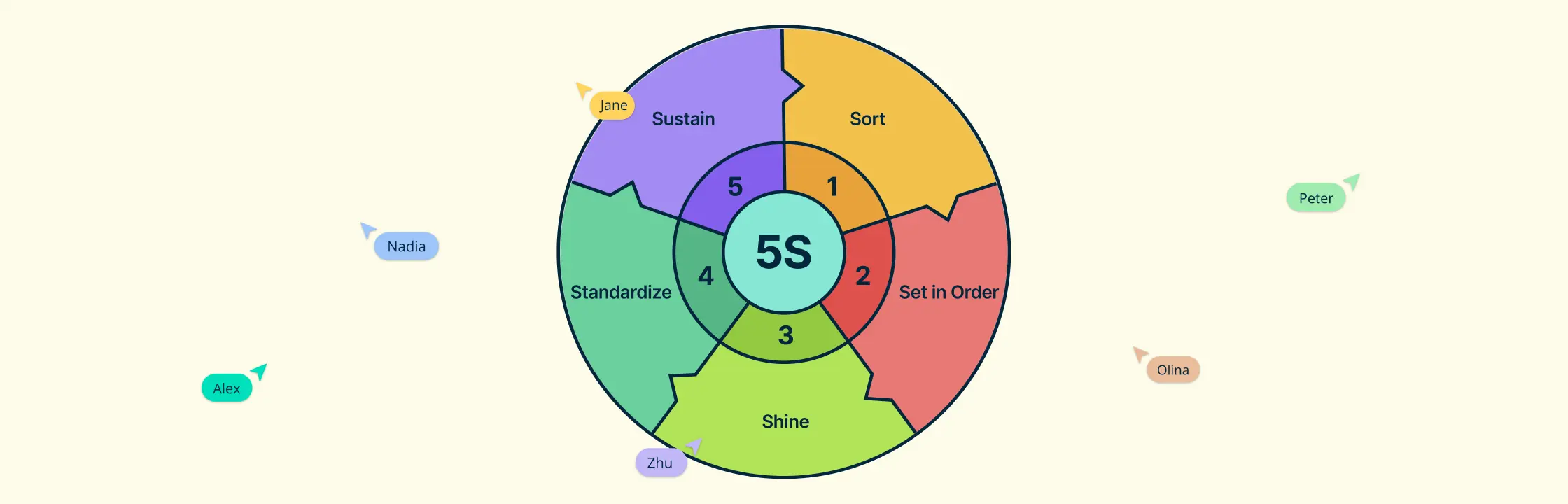

The 5S methodology is a lean management tool designed to help organizations maintain clean, organized, and efficient workspaces. The term “5S” comes from five Japanese words that start with the letter “S,” each representing a step in the process:

- Sort (Seiri): Remove unnecessary items to clear clutter.

- Set in Order (Seiton): Arrange essential items for easy access.

- Shine (Seiso): Keep the workplace clean and organized.

- Standardize (Seiketsu): Establish consistent practices to maintain order.

- Sustain (Shitsuke): Ensure that these practices are followed over time.

By following these five steps, businesses can reduce waste, enhance safety, and improve operational efficiency. The 5S methodology is widely used in various industries, from manufacturing and healthcare to offices and retail environments.

What Is 5S Used For?

The 5S methodology is widely used to create organized, efficient, and safe workplaces across various industries. Initially developed for manufacturing, 5S has expanded into sectors such as healthcare, education, office environments, and more. Its primary purpose is to streamline operations by eliminating waste, improving workflow, and maintaining consistent standards of cleanliness and organization. Here’s how 5S is applied in different contexts:

Workplace Organization:

5S helps declutter and arrange workspaces so that tools, materials, and equipment are easily accessible. By reducing the time spent searching for items, employees can focus on productive tasks, leading to higher efficiency and reduced downtime.

Safety Enhancement:

A key benefit of 5S is its focus on maintaining a safe work environment. By organizing the workspace and ensuring everything is in its proper place, hazards are minimized, which reduces the risk of accidents. Industries like manufacturing and healthcare especially benefit from 5S’s emphasis on safety.

Waste Reduction:

5S is instrumental in identifying and eliminating waste—whether it’s excess materials, outdated tools, or inefficiencies in workflow. The system helps companies optimize the use of resources, thereby lowering costs and improving overall operational efficiency.

Standardization:

Implementing 5S ensures that processes are standardized across teams and departments. This consistency reduces errors, promotes best practices, and makes it easier to onboard new employees. Standardization also simplifies quality control and performance monitoring.

Employee Engagement:

5S encourages employees to take ownership of their workspace and participate actively in maintaining organization and cleanliness. This involvement fosters a sense of responsibility and pride, leading to greater job satisfaction and higher overall morale.

Origins of the 5S Methodology

The 5S methodology was developed in Japan, in the 1960s by Hiroyuki Hirano. It was primarily used along with a lean manufacturing philosophy that revolutionized modern production practices. The 5S methodology was born out of the desire to create an organized and efficient working environment, serving as a foundation for other lean practices such as Just-in-Time (JIT) production and Kaizen. This system became a revolutionary approach to manufacturing, emphasizing efficiency, waste reduction, and continuous improvement— all central to the 5S methodology. Over time, this methodology has expanded beyond manufacturing and is now a core element in lean management systems globally.

The Toyota Production System (TPS)

A key example of early adaptation of the 5S methodology is the Toyota Production System. TPS was Toyota’s response to the challenges of post-war manufacturing. Inspired by early efficiency strategies such as Henry Ford’s assembly line, TPS refined these 5S concepts into a more flexible and waste-conscious approach. At the heart of TPS was a deep commitment to lean manufacturing, which sought to eliminate all forms of waste (known as “muda”) while delivering the highest possible value to customers.

Expansion Beyond Manufacturing

Although the 5S methodology was originally designed to optimize production processes on the factory floor, its principles have since transcended the manufacturing industry. Today, organizations across various sectors, including healthcare, logistics, education, and even offices, are adopting 5S to improve efficiency, safety, and overall operational performance. The versatility of 5S makes it an integral part of lean management systems worldwide, enabling businesses to standardize processes, maintain cleanliness, and foster a culture of continuous improvement.

Benefits of the 5S Methodology in the Workplace

The 5S methodology offers numerous benefits to businesses across industries. By emphasizing organization, cleanliness, and standardization, companies can foster an environment where efficiency and safety are top priorities. Let’s explore some of the most significant benefits in detail.

Increased Efficiency

One of the primary goals of the 5S methodology is to streamline workplace processes. By ensuring tools, materials, and documents are always in their designated places, employees no longer waste time searching for essential items. This results in smoother operations and faster turnaround times. For example, manufacturing teams can reduce downtime, while office environments benefit from better file management systems. Ultimately, operational efficiency soars, contributing to more productive workflows.

Improved Safety

A well-organized workspace is a safer one. By applying the 5S principles, businesses can reduce clutter, clear unnecessary items, and designate safe areas for hazardous materials or machinery. This proactive approach significantly reduces the risk of workplace accidents, such as trips, falls, or equipment malfunctions. Implementing workplace safety protocols via 5S can lower insurance costs and ensure compliance with health and safety regulations.

Enhanced Productivity

When employees work in a clean and structured environment, they are more focused and less likely to make mistakes. The 5S methodology fosters this kind of productive atmosphere by eliminating distractions and inefficiencies. Whether it’s reducing the need to walk across a cluttered space to find a tool or keeping digital files organized for quick access, these improvements drive higher levels of output with fewer errors. Increased productivity means that teams can accomplish more in less time, positively impacting the bottom line.

Cost Reduction

Cost savings are a natural outcome of implementing the 5S methodology. By cutting down on wasted materials, time, and resources, businesses can allocate their budget more effectively. Additionally, fewer workplace accidents and mistakes lead to reduced downtime and less spending on repairs or medical bills. Through waste reduction and better resource utilization, companies can achieve significant cost savings over time, making 5S an excellent return on investment.

Employee Engagement

One of the often-overlooked benefits of the 5S methodology is its positive impact on employee morale and engagement. When workers are actively involved in the 5S implementation process, they take ownership of their workspace, resulting in a sense of pride and accountability. This engagement can lead to a more motivated workforce, lower turnover rates, and a stronger team culture. Employees who feel empowered to contribute to improvements are also more likely to suggest new ideas, driving continuous improvement and innovation.

The 5S Process: Step-by-Step Implementation

To effectively implement the 5S methodology, each step must be carried out methodically to create lasting improvements. By following these stages in sequence, organizations can transform their workplaces into highly efficient, safe, and organized environments. Let’s dive into each of the five steps in detail, complete with practical examples.

1. Sort (Seiri)

The first step in the 5S methodology is ‘Sort’, which focuses on eliminating unnecessary items from the workspace. This process helps reduce clutter and ensures that only essential tools, materials, and documents are kept.

Start by categorizing all items in your workspace. Identify what is essential for daily operations and what is no longer needed.

Use the ‘red tag’ technique to mark items that need further evaluation. Place a red tag on items that are rarely used, broken, or outdated, and then decide whether to keep, donate, recycle, or dispose of them after further review.

For example, in a manufacturing facility, sorting might involve removing old or malfunctioning tools that clutter the workspace. Similarly, in an office environment, Sort might involve going through filing cabinets and discarding outdated paperwork or archiving digital files. This decluttering ensures that workers only have access to what is necessary, reducing time spent searching for resources.

Use diagrams like Affinity Diagram tool and Red-Tagging Charts to categorize items and track those that need further review. A Decision Matrix Template helps evaluate whether items should be kept, discarded, or stored.

2. Set in Order (Seiton)

After removing unnecessary items, the next step is ‘Set in Order’. This phase involves organizing tools, materials, and equipment so that everything has a designated place and is easily accessible. The objective is to improve workflow by making items easy to find and access.

Clearly label storage areas, tools, and materials to ensure everything is easy to locate. Group similar items together and store frequently used tools within easy reach.

Utilize visual management tools like color-coding, labels, and signs to guide employees on where items should be placed.

For instance, in a warehouse, placing high-demand inventory on easily accessible shelves (at waist height) reduces the amount of time workers spend reaching for or searching for products. In an office, labeling file cabinets and using desk organizers for stationery helps employees quickly find what they need, minimizing time spent searching for documents or tools.

Diagrams like the Spaghetti Diagram and Workflow Diagram visualize the optimal arrangement of tools and materials. A Floor Plan Diagram can help design an efficient workspace layout ensuring everything has a designated place.

3. Shine (Seiso)

The third step ‘Shine’ involves cleaning and maintaining the workspace to ensure it is always in top condition. This step is not just about cleanliness but also about inspecting the area for potential issues like wear and tear or equipment malfunctions before they escalate.

Establish a daily cleaning routine, assigning specific cleaning tasks to team members. Regular cleaning prevents the accumulation of dust, grime, or equipment failures.

Use cleaning as an opportunity to inspect tools, machinery, and workspaces for signs of damage or deterioration.

The Shine phase is important in every workspace, and critical in certain situations like healthcare environments. Sterile and clean workspaces are essential to prevent infections and ensure patient safety. Daily cleaning and inspection routines can identify broken or malfunctioning equipment before it poses a risk. In an industrial setting, regular cleaning helps keep machines running smoothly and reduces the risk of costly breakdowns.

Cleaning checklists and maintenance flowcharts ensure regular cleaning and inspection tasks are performed consistently. Use an inspection checklist to keep the workspace in top condition.

4. Standardize (Seiketsu)

After successfully implementing Sort, Set in Order, and Shine, the next step is to ‘Standardize’ these practices. This ensures that all previous improvements are maintained consistently over time. Standardization is key to embedding these processes into the organizational culture.

Create standardized procedures, checklists, and schedules that everyone in the organization can follow. Make sure these standards are clearly communicated to all team members.

Develop a system for monitoring adherence to the 5S standards, such as regular audits or daily check-ins.

In an office setting, Standardize might involve creating a weekly checklist to ensure that all desks are decluttered, documents are properly filed, and common areas are clean. For a factory floor, visual reminders and posted schedules can help ensure that machines are maintained regularly and that tools are always returned to their designated spots after use.

Visual tools like Standard Operating Procedure (SOP) diagrams and checklists standardize processes. A Process Flow Diagram Tool ensures that cleaning and organizing tasks are regularly followed.

5. Sustain (Shitsuke)

The final step in the 5S methodology is to ‘Sustain’ the improvements made. To achieve long-term success, organizations need to continually reinforce the 5S principles. This step is about creating a culture of discipline where employees take ownership of maintaining the improvements.

Conduct regular 5S audits to measure compliance and identify areas for improvement. Audits ensure that the organization continues to benefit from the 5S system over time.

Provide ongoing training and workshops to reinforce the importance of the 5S methodology. Engaging employees through education and involvement is essential to sustaining the improvements made.

In manufacturing plants, regular 5S audits ensure that tools remain organized and safety standards are upheld. Employees may also be encouraged to participate in monthly 5S meetings, where they can share ideas for improving workplace organization or suggest new solutions for waste reduction. This continuous feedback loop keeps everyone engaged and helps ensure that the 5S system is a permanent part of the workplace culture.

Audit checklists and PDCA Cycle diagrams are essential for monitoring ongoing compliance and continuous improvement. A training matrix tracks employee engagement with 5S practices, ensuring sustainability over time.

Common Challenges in Implementing the 5S Methodology

While the 5S methodology offers tremendous benefits, implementing it successfully can come with several challenges. However, with proactive strategies and careful planning, these challenges can be managed effectively. Here are some of the most common hurdles and how to overcome them:

1. Resistance to Change

One of the most significant challenges in implementing the 5S methodology is employee resistance. Workers who are comfortable with their existing routines may view the introduction of 5S as disruptive. Resistance to change is natural, especially if employees feel that the new system will add complexity or take time away from their core responsibilities.

Involve Employees Early: The best way to minimize resistance is by involving employees in the 5S implementation process from the outset. Solicit their input on how to improve the workspace and integrate their feedback into the 5S system. When workers feel like they have a say in the changes, they are more likely to embrace them.

Communicate the Benefits: Highlight the long-term benefits of the 5S methodology, such as reduced frustration due to clutter, improved safety, and increased productivity. Provide real-world examples of how 5S has improved operations in other organizations. If employees understand the “why,” they are more likely to support the initiative.

Offer Training and Support: Provide comprehensive training to ensure employees understand each phase of the 5S system and how it will impact their daily work. Encourage open communication to address any concerns they may have about the process.

2. Sustaining Improvements

Another common challenge is sustaining the improvements made by the 5S methodology over time. After the initial implementation, it’s easy for teams to revert to old habits, leading to clutter and disorganization creeping back in. The key to overcoming this challenge is building 5S discipline into the workplace culture.

Regular Audits: Conduct 5S audits regularly to ensure compliance with the system. Audits should be done by both managers and employees to create a sense of shared responsibility. Use the audits to identify areas for improvement and provide recognition to teams that maintain high standards.

Ongoing Training and Refresher Courses: As the 5S system evolves, employees may need periodic training to reinforce the principles and address any gaps. Refresher courses and workshops keep the 5S mindset alive and encourage continuous improvement.

Employee Engagement: Keep employees engaged by creating opportunities for them to suggest changes and improvements. Consider forming a 5S team that meets regularly to assess how the methodology is being applied and to brainstorm ideas for refining it.

3. Customizing 5S

Although the 5S methodology is a highly effective system, it’s not a one-size-fits-all solution. Different industries and organizations have varying needs, so the implementation of 5S must be tailored to fit the unique context of each workplace. Rigid application of the methodology without adapting to specific requirements can lead to frustration and inefficiencies.

Flexibility in Application: Rather than following a strict, unchangeable 5S template, allow some flexibility in how the methodology is implemented. Different departments may require different approaches to sorting, organizing, and cleaning. For example, what works for a manufacturing floor might not be ideal for a hospital or office environment.

Focus on Core Principles: While adapting the methodology, ensure that the core principles of Sort, Set in Order, Shine, Standardize, and Sustain remain intact. Customizing 5S doesn’t mean abandoning its core values; it simply means tailoring its execution to better suit your organization’s needs.

Pilot Programs: Before rolling out 5S across the entire organization, consider starting with a pilot program in a single department or area. This allows you to test the customized version of 5S and make any necessary adjustments before full-scale implementation.

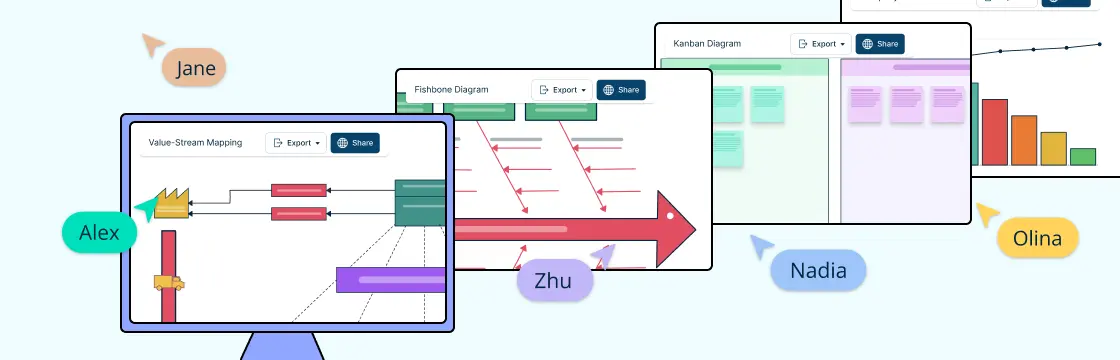

How to Use 5S Templates on Creately

Using 5S templates on Creately simplifies the implementation of the 5S methodology by offering an interactive and visual platform for organizing your workspace. Creately’s easy-to-use interface allows teams to collaborate in real-time, ensuring everyone stays aligned during the 5S process. Here’s a step-by-step guide to using a 5S template on Creately:

1. Select or Customize a Template

Creately offers a variety of pre-built 5S templates that can be used to kick-start your organization process. Choose from templates for red-tagging charts, checklists, workflow diagrams, and more. If needed, you can easily customize these templates to suit your specific needs.

2. Collaborate in Real Time

Invite your team to work on the template simultaneously. For example, during the Sort phase, employees can use a red-tagging chart to flag unnecessary items. Everyone can provide input, ensuring that decisions are made collectively and efficiently.

3. Organize with Visual Tools

Use Creately’s visual tools like color-coded labels, connectors, and icons to represent different items, actions, or areas in the workspace. This makes the Set in Order phase more intuitive, allowing you to create a clear and easily understandable layout for the workspace.

4. Track and Maintain Progress

During the Shine and Standardize phases, you can use Creately to create and update cleaning schedules or audit checklists. The visual nature of Creately helps you monitor progress, making it easy to spot areas that need attention or improvement.

5. Sustain with Documentation

In the final Sustain phase, keep your 5S template as a living document. Creately allows you to regularly update templates, track compliance, and share reports with your team, ensuring that 5S practices are consistently maintained.

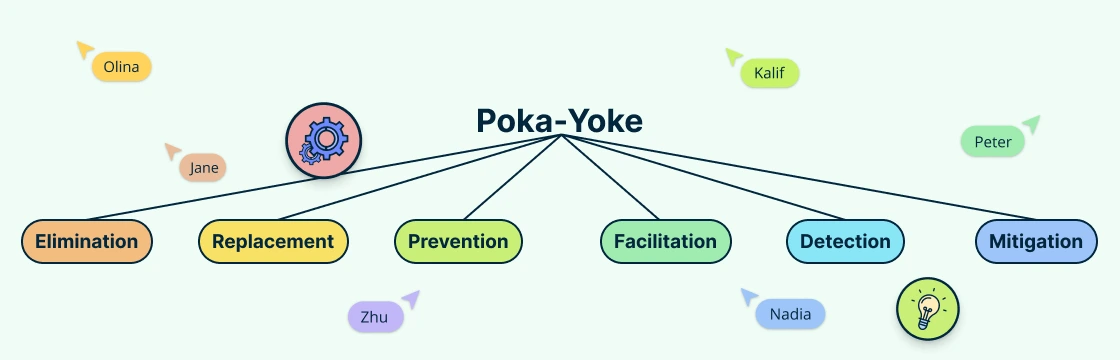

Essential 5S Templates for Streamlined Implementation

Using 5S templates can simplify the implementation of the methodology by providing structured tools for each stage of the process. These templates offer visual guidance, helping teams stay organized, track progress, and maintain consistency across the workspace. By utilizing these templates, businesses can standardize their approach to 5S and ensure long-term success in creating efficient, safe, and well-organized environments.

Final Thoughts: Transforming Your Workplace with 5S

The 5S methodology is more than just a system for tidying up. It’s a comprehensive approach to creating an organized, safe, and highly efficient workplace. By embracing the five steps—Sort, Set in Order, Shine, Standardize, and Sustain—businesses can not only eliminate waste but also foster a culture of continuous improvement.

What sets the 5S methodology apart is its versatility. Whether you’re in manufacturing, healthcare, education, or any industry, 5S can be tailored to fit your organization’s unique needs. The result is a workplace that operates smoothly, with enhanced productivity, fewer accidents, and more engaged employees who take pride in their organized environment.

The benefits of the 5S methodology are clear and measurable. Begin your journey today, and transform your workspace into a model of efficiency, safety, and excellence.