In today’s rapidly evolving business landscape, the ability to effectively manage and optimize supply chains has become more critical than ever. Supply Chain Visualization offers organizations a powerful means of transforming complex data into clear, actionable insights. By creating visual representations of supply chain processes, businesses can enhance their understanding of how products flow from suppliers to customers, identify potential bottlenecks, and make informed decisions that drive efficiency. This guide explores the fundamentals of supply chain visualization, delving into its significance and various applications, and providing a roadmap for organizations seeking to improve their operational effectiveness and responsiveness in an increasingly competitive market.

What Is Supply Chain Visualization?

Supply chain visualization is an essential tool that allows businesses to gain a clear, visual representation of their overall supply chain processes. This approach provides a comprehensive view of the interconnected network of suppliers, manufacturers, distributors, and retailers. By illustrating the flow of materials, information, and finances, visualization helps stakeholders understand intricate supply chain dynamics. It acts like a detailed map, guiding decisions, optimizing operations, and enhancing communication across different parts of the supply chain.

Supply chain diagrams, a significant aspect of this visualization process, offer a snapshot of the supply chain’s anatomy. They underline various phases such as procurement, production, distribution, and delivery, making identifying inefficiencies and areas needing improvement easier. These diagrams are crucial for supply chain managers and logistics professionals as they provide insights into improving efficiency and reducing bottlenecks.

Why Supply Chain Visualization Matters

Visualization tools have become indispensable in the ever-evolving landscape of global supply chains. They not only help in foreseeing potential disruptions but also in strategizing effective risk management. Through data visualization, companies can translate complex data sets into understandable insights, thus improving decision-making processes. The real-time visibility offered by these tools aids in tracking inventory levels, evaluating supplier performance, and analyzing demand forecasts, which are vital for maintaining a seamless supply chain operation. Moreover, visualization fosters better collaboration amongst stakeholders by providing a platform where information is portrayed in a common language that is understandable by all, thus enhancing strategic planning and operational management.

1. Identify Bottlenecks

One of the most significant advantages of supply chain visualization is its ability to identify bottlenecks. In any supply chain, delays can occur at various stages, whether due to resource shortages, inefficient processes, or unexpected disruptions. By visualizing the entire supply chain, businesses can easily pinpoint these problematic areas. This visualization acts like a magnifying glass, allowing teams to see where slowdowns happen, enabling them to implement timely interventions. For instance, if a certain supplier consistently causes delays, management can investigate and either negotiate better terms or find alternative sources, thereby minimizing disruptions.

2. Enhance Collaboration

Moreover, clear and well-structured diagrams enhance collaboration among teams and stakeholders. In organizations where different departments such as procurement, production, and logistics must work together, misunderstandings can lead to inefficiencies and errors. Visual tools create a shared language, ensuring that everyone understands the supply chain’s layout and how their roles fit into the bigger picture. When teams have access to the same visual data, it fosters open communication and encourages collaboration, making it easier to align strategies and objectives.

3. Streamline Processes

Another critical benefit of Supply Chain Visualization is its ability to streamline processes. Mapping out the supply chain allows organizations to visualize each step, from sourcing materials to delivering products to customers. This clarity can help identify redundancies or unnecessary steps that can be eliminated to enhance efficiency. For example, if a company sees that certain tasks are duplicated across departments, it can streamline operations by consolidating these efforts, ultimately saving time and resources. The result is a more agile supply chain that can respond swiftly to changes in demand or market conditions.

4. Improve Forecasting

Additionally, visualization tools significantly improve forecasting capabilities. By highlighting trends and patterns, businesses can gain insights into customer behavior, seasonal fluctuations, and market demands. With a clear visual representation of historical data, organizations can make more accurate predictions about future needs, helping them optimize inventory levels and reduce excess stock. This predictive power is essential in today’s market, where consumer preferences can shift rapidly. By anticipating changes, businesses can respond proactively, ensuring they have the right products available at the right time.

5. Logistics Design

Finally, logistics design is a vital aspect of supply chain management that benefits immensely from visualization. The ability to visualize supply routes and logistics operations enables businesses to design more efficient delivery paths. By using visual tools to map out transportation routes, organizations can assess various factors such as traffic patterns, delivery schedules, and vehicle capacities. This strategic approach allows companies to optimize transportation costs and minimize delivery times, ensuring that goods reach their destinations swiftly and reliably.

Supply chain visualization is not just about creating pretty diagrams; it is about harnessing the power of visual representation to drive meaningful business improvements. From identifying bottlenecks and enhancing collaboration to streamlining processes and improving forecasting, these tools are essential for any organization aiming to navigate the complexities of modern supply chains effectively.

How Simple Tools Enhance Supply Chain Visualization

Using tools like process flow maps and other diagramming techniques, teams can visualize complex supply chain systems clearly and intuitively. Here’s how these tools, which can be created on platforms like Creately, aid in supply chain visualization:

1. Process Flow Maps

Process flow maps break down the steps in the supply chain, helping teams see how raw materials progress through production, storage, and distribution to the end customer. With Creately, teams can easily build flow maps that show each step, making it simple to pinpoint bottlenecks or inefficiencies. This clarity supports process improvement by identifying redundant tasks or delays, allowing for a smoother and more efficient workflow.

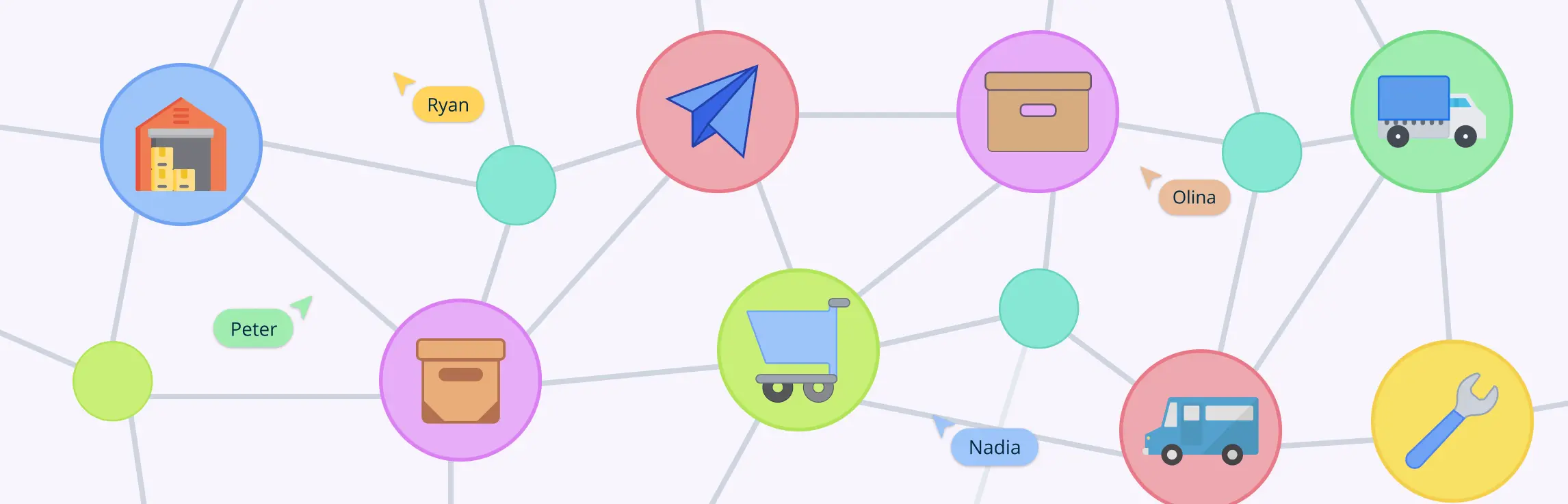

2. Network Diagrams

Network diagrams visualize the relationships between suppliers, manufacturers, distribution centers, and other key players in the supply chain. By mapping these connections, companies can identify dependencies and better understand how changes in one part of the network affect the rest. Network diagrams are also invaluable for understanding the scope of impact in the case of supplier changes or disruptions, helping with risk mitigation and contingency planning.

3. Heat Maps

Heat maps are color-coded diagrams that show data intensity across the supply chain, such as areas with high demand, costs, or resource allocation. For instance, they can indicate regions with the highest transportation costs or longest delivery times. This insight enables businesses to allocate resources more effectively, ensuring that high-demand areas receive priority or cost-heavy areas are optimized to reduce expenses.

4. Geographic Maps

Geographic maps help visualize supply chain operations across different locations. By marking supplier locations, warehouses, and distribution centers, organizations can analyze geographic layouts and optimize routes or identify areas prone to delays. Geographic mapping also assists in logistics planning, helping companies balance inventory across locations to meet regional demand efficiently.

5. Sequence Diagrams

Sequence diagrams show interactions between different components of the supply chain in a sequential flow. They are especially useful for visualizing communication or process flows across departments, such as the sequence from order placement to delivery. By understanding these sequences, companies can streamline processes, improve coordination among departments, and enhance overall supply chain responsiveness.

6. Dashboards

Dashboards consolidate real-time data and key performance indicators (KPIs) into a single view, providing managers with insights into metrics like order fulfillment rates, lead times, and inventory levels. Having all this information on a Creately dashboard allows for quick analysis, better decision-making, and immediate detection of potential issues. Dashboards are vital for daily operations, as they provide a clear overview of the supply chain’s health and performance.

7. Sankey Diagrams

Sankey diagrams are flow diagrams that show the proportional flow of resources through different supply chain stages, from materials to finished goods. These diagrams illustrate where resources are concentrated or dissipated along the supply chain, helping identify inefficiencies or points of waste. Sankey diagrams are particularly useful for assessing energy or cost flows, giving companies an opportunity to optimize high-cost or high-resource areas.

8. Control Charts

Control charts are statistical tools used to monitor and control processes by displaying data points over time with set control limits. In the context of supply chain visualization, control charts help track key metrics, such as delivery times, inventory levels, and production outputs, enabling organizations to detect variations and identify potential issues. By visualizing whether processes are within acceptable limits, companies can manage quality and maintain consistency. If data points start to drift outside control limits, managers can take corrective action to prevent issues before they affect the broader supply chain.

9. Gantt Charts

Gantt charts are time-based visual tools used to plan and track the timing of various supply chain activities, from procurement and production to distribution. In supply chain management, Gantt charts help schedule each process step, set deadlines, and allocate resources efficiently. This visual representation makes it easy to spot overlapping tasks, adjust schedules to avoid bottlenecks, and ensure that tasks are completed on time. By laying out each part of the process in a timeline format, Gantt charts support better project management, making them ideal for coordinating complex supply chain projects and improving communication among teams.

10. Critical Path Analysis

Critical path analysis (CPA) is a technique that identifies the longest sequence of dependent tasks in a project, determining the minimum time required to complete the entire process. In supply chain visualization, CPA helps businesses identify critical tasks that directly impact the project timeline, highlighting areas that must stay on track to avoid delays. By understanding the critical path, managers can prioritize resources and focus on the activities that have the most significant impact on project completion. CPA is especially useful in supply chain project planning, where delays in one task could lead to costly setbacks in production or distribution.

Applications of Supply Chain Visualization

Supply chain visualization is a versatile tool that can be applied across various stages of the supply chain, providing organizations with valuable insights and improving operational efficiency. Here are some key applications of supply chain visualization:

1. Mapping the Supply Chain Network

One of the primary applications of supply chain visualization is creating detailed maps of the entire supply chain network. These maps illustrate the flow of materials, information, and finances from suppliers to manufacturers to end consumers. By visualizing this network, companies can identify critical nodes, understand the relationships between different actors, and recognize potential vulnerabilities. This comprehensive overview enables organizations to optimize their supply chain structure, enhancing responsiveness and agility.

2. Inventory Management

Effective inventory management is vital for maintaining a balance between supply and demand. Supply chain visualization tools help businesses monitor inventory levels across different locations, visualize stock movements, and forecast future inventory needs. By employing visual dashboards that display real-time data on inventory levels and turnover rates, organizations can make informed decisions about reordering and stock replenishment. This application not only reduces the risk of stockouts or overstock situations but also minimizes carrying costs and waste.

3. Performance Monitoring and Reporting

Visualizations play a crucial role in performance monitoring by providing key performance indicators (KPIs) in an easily digestible format. Organizations can utilize dashboards to track metrics such as order fulfillment rates, lead times, transportation costs, and supplier performance. By visualizing these metrics, decision-makers can quickly identify areas needing improvement and take corrective actions. Furthermore, regular reporting through visual tools enhances transparency and accountability across the supply chain, fostering a culture of continuous improvement.

4. Risk Management

In an increasingly volatile global market, effective risk management is paramount. Supply chain visualization can help organizations identify and assess risks by mapping out potential disruptions, such as natural disasters, supplier failures, or geopolitical issues. By visualizing these risks and their potential impact on the supply chain, businesses can develop contingency plans and mitigation strategies. This proactive approach enables companies to respond quickly to disruptions, minimizing downtime and protecting revenue.

5. Scenario Planning and Simulation

Visualization tools enable organizations to conduct scenario planning and simulations to anticipate how various changes may impact their supply chain. For example, businesses can visualize the effects of changes in supplier locations, production capacities, or transportation routes on overall performance. By modeling different scenarios, companies can better prepare for potential disruptions and make strategic decisions that optimize their operations. This application is particularly valuable in today’s rapidly changing business environment, where agility and foresight are essential for success.

6. Collaboration and Communication

Supply chain visualization fosters collaboration among various stakeholders, including suppliers, manufacturers, distributors, and retailers. By providing a common visual reference, organizations can enhance communication and ensure everyone is aligned with the overall supply chain strategy. This collaborative approach facilitates problem-solving, as stakeholders can easily identify issues and brainstorm solutions together. Additionally, visualizations can be shared with external partners, creating a more transparent and cooperative supply chain environment.

7. Customer Experience Enhancement

Effective supply chain visualization can significantly improve customer experience. By providing insights into order status, delivery timelines, and product availability, businesses can enhance communication with customers and manage their expectations more effectively. Visual tools can help organizations identify bottlenecks that may delay deliveries, allowing them to proactively communicate with customers and offer alternatives. This level of transparency not only builds trust but also fosters customer loyalty.

The applications of supply chain visualization extend beyond mere mapping; they encompass various strategies that enhance efficiency, collaboration, and responsiveness. By leveraging visual tools throughout the supply chain, organizations can navigate complexities with ease and position themselves for long-term success.

Helpful Resources

Use mind map online to visualize ideas and concepts for collaborative brainstorming, creative thinking, problem-solving, and so much more.

Create timelines for any event; track and analyze your team’s projects and tasks from start to finish with Creately’s Gantt chart maker.

Model your supply and demand data to anticipate future trends. Pinpoint inefficiencies and costs in processes on a single easily shareable workspace.

This Gantt chart tutorial will help you master the art of creating visual timelines for tasks and milestones

Supply Chain Visualization with Creately

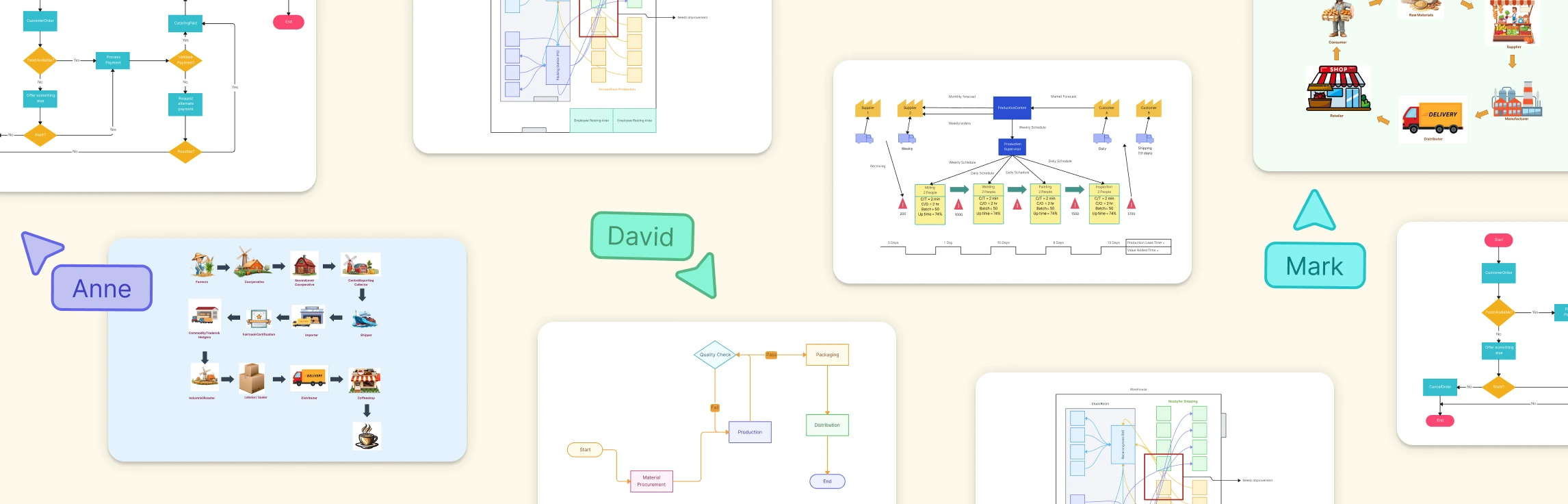

Supply chain visualization has seen a transformative leap with Creately’s intuitive visual workspace designed to enhance collaboration and visualization. Through its expansive toolset, Creately allows users to create comprehensive supply chain diagrams that illustrate complex networks in a way that is both easily understandable and actionable.

Comprising features such as AI data visualization and collaborative strategic planning, Creately maximizes operational effectiveness. It offers a seamless interface to visualize supply chains by employing graphical elements including flowcharts for inventory tracking, icons for process mapping, and network diagrams for logistics design. The platform’s strength lies in its ability to facilitate real-time collaboration among stakeholders, thus improving communication and reducing the time taken to make informed decisions.

Another standout feature of Creately is its capability to integrate with a variety of data sources, allowing for the automated updating of visualizations as data changes. This feature is particularly useful for resource planning and business process management, where dynamic data can alter supply chain strategies quickly. By using Creately, companies can ensure that they are always working with the most current information, enabling them to anticipate potential disruptions and adjust strategies accordingly.

Summary

As we’ve explored, supply chain visualization serves as a pivotal tool in transforming complex logistical networks into clear, actionable insights. Tools like Creately are at the forefront of this transformation, enhancing decision-making by providing comprehensive supply chain diagrams and fostering strategic collaboration. From improving inventory management and logistics design to facilitating better forecasting, visualization is crucial for supply chain optimization.

Adopting visualization strategies is not just about embracing technology; it’s about revolutionizing how supply chains operate. By integrating tools such as Creately, businesses are not only optimizing operations but also enhancing communication and collaboration amongst stakeholders. The ability to visualize supply chain dynamics paves the way for more efficient, responsive, and transparent supply chain processes, ultimately leading to operational excellence.

FAQs About Supply Chain Visualization

What is supply chain visualization, and how does it work?

Why is supply chain visualization important for businesses?

What are the key benefits of implementing supply chain visualization tools?

Implementing supply chain visualization tools offers several key benefits, including:

- Enhanced visibility into supply chain processes, allowing for better tracking of goods and information.

- Improved collaboration among stakeholders by providing a common visual reference.

- The ability to identify inefficiencies and streamline operations, leading to cost savings.

- Better forecasting and planning capabilities through the analysis of trends and historical data.

- Proactive risk management by visualizing potential disruptions and their impact on the supply chain.

How can supply chain visualization improve inventory management?

What types of supply chain visualization techniques are commonly used?

Common supply chain visualization techniques include:

- Flowcharts and process maps to illustrate the steps involved in the supply chain.

- Gantt charts for scheduling and tracking project timelines.

- Geographic information systems (GIS) to map transportation routes and logistics operations.

- Dashboards that provide real-time data on key performance indicators (KPIs) related to supply chain performance.

- Network diagrams that depict relationships and interactions among various entities in the supply chain. These techniques help organizations gain a comprehensive understanding of their supply chain dynamics and make data-driven decisions.

Resources:

Basole, R.C., Bellamy, M.A. and Park, H. (2016). Visualization of Innovation in Global Supply Chain Networks. Decision Sciences, 48(2), pp.288–306. doi:www.doi.org/10.1111/deci.12213.

Khakpour, A., Colomo-Palacios, R. and Martini, A. (2021). Visual Analytics for Decision Support: A Supply Chain Perspective. IEEE Access, 9, pp.81326–81344. doi:www.doi.org/10.1109/access.2021.3085496.

Lou, C.X., Alessio Bonti, Prokofieva, M., Abdelrazek, M. and Kari (2020). Literature Review on Visualization in Supply Chain & Decision Making. 2020 24th International Conference Information Visualisation (IV), [online] 6, pp.746–750. doi:www.doi.org/10.1109/iv51561.2020.00019.