If you run a business that sells physical products, you know how important it is to keep track of your inventory. Inventory management is the process of planning, organizing, and controlling your stock levels to meet customer demand and avoid overstocking or running out of products. Inventory management techniques are the methods and tools you use to optimize your inventory management process.

In this blog post, we will explore some of the most effective inventory management techniques that can help you improve your business operations, reduce costs, and increase profits.

What is Inventory Management?

Inventory management is the process of keeping track of what you have, where it is, and how much it costs. It’s a crucial part of running a business, whether you sell physical products or services. Inventory management helps you optimize your cash flow, avoid stock outs or overstocking, and improve customer satisfaction.

There are different types of inventory, such as raw materials, work-in-progress, finished goods, and spare parts. Each type has its own challenges and requires different strategies to manage effectively.

Read more on how to use inventory templates to streamline your stock.Why is Inventory Management Important?

Poor inventory management affects your bottom line. It can lead to:

Overstocking: You waste money on storage costs, spoilage, and obsolescence.

Understocking: You lose sales and customers due to stockouts and delays.

Inaccuracies: You make wrong decisions based on unreliable data.

On the other hand, good inventory management can help you:

Reduce costs: You optimize your inventory levels and avoid unnecessary expenses.

Increase sales: You meet customer demand and offer faster delivery.

Improve quality: You ensure product availability and freshness.

Enhance productivity: You streamline your operations and reduce errors.

Seven Essential Inventory Management Techniques

1. ABC Analysis

This technique involves categorizing your inventory items based on their value and importance. The most valuable items are labeled as A, the moderately valuable items as B, and the least valuable items as C. Then, you allocate more resources and attention to the A items, less to the B items, and the least to the C items. This way, you can prioritize your inventory management efforts and optimize your cash flow.

2. EOQ Formula

This technique involves calculating the optimal order quantity for each item. The Economic Order Quantity (EOQ) formula considers the demand rate, the ordering cost, and the holding cost of each item. The goal is to minimize the total cost of ordering and holding inventory. The EOQ formula is:

EOQ = √(2 x D x S / H)

Where:

D = Annual demand in units

S = Ordering cost per order

H = Holding cost per unit per year

By using the EOQ formula, you can determine how much to order and when to order each item.

3. JIT Method

This technique involves ordering and receiving inventory just in time for production or sales. The JIT method reduces the need for storage space and eliminates the risk of overstocking or understocking. However, it requires accurate forecasting, reliable suppliers, and flexible production processes. The JIT method is suitable for businesses that deal with perishable or fast-moving items.

4. Cycle Counting

This technique involves counting a small portion of your inventory on a regular basis. For example, you can count 10% of your inventory every week until you cover the entire inventory in 10 weeks. Then, you repeat the cycle. Cycle counting helps you maintain accurate inventory records and identify any discrepancies or issues. It also reduces the disruption caused by annual physical counts.

5. FIFO

FIFO stands for First In, First Out, and it’s a way of managing your inventory that makes sure you sell the oldest items first.

Why is this important? Well, imagine you’re running a grocery store and you have a bunch of bananas on your shelves. You don’t want to sell the ones that you just got from your supplier, because they’re fresh and have a longer shelf life. You want to sell the ones that have been sitting there for a while, because they’re more likely to go bad soon. That way, you reduce waste and increase customer satisfaction.

FIFO helps you do that by keeping track of when you received each batch of items and making sure you sell them in the same order. FIFO is also useful for accounting purposes, because it gives you a more accurate picture of your cost of goods sold and your profit margin. By using FIFO, you can match your sales revenue with the actual cost of the items you sold, rather than the cost of the items you bought most recently. This can help you avoid overestimating or underestimating your income and expenses.

6. LIFO

LIFO stands for Last In, First Out. It’s a way of managing inventory that assumes that the last items you bought or produced are the first ones you sell. This means that the items left in your inventory are the oldest ones.

Why would you use LIFO? Well, one reason is to save on taxes. If the prices of your items are rising over time, then selling the newest ones first means that your cost of goods sold is higher, and your taxable income is lower, which is beneficial for your bottom line.

But LIFO also has some drawbacks. For one thing, it doesn’t reflect the actual flow of goods in most businesses. Usually, you sell the oldest items first, not the newest ones. That’s why LIFO is not allowed under some accounting standards, like IFRS. Another problem is that LIFO can distort your inventory value. If you have a lot of old items in your inventory that you bought at low prices, then your inventory value will be understated compared to the current market value. That can affect your balance sheet and your financial ratios.

LIFO is a method of inventory management that has some advantages and disadvantages. You should use it carefully and only if it makes sense for your business and your industry.

7. Inventory Management Software

This technique involves using a software system that automates and simplifies your inventory management tasks. Inventory management software can help you:

Track your inventory levels in real-time

Generate purchase orders and invoices

Manage multiple warehouses and locations

Integrate with other systems such as accounting, e-commerce, or CRM

Analyze your inventory performance and trends

Create reports and dashboards

Factors to Consider When Choosing the Right Inventory Management Technique for Your Business

Choosing the right inventory management technique for your business depends on several factors, such as:

Type and nature of your products: Are they perishable, seasonal, or fast-moving? Do they have a high or low turnover rate? Do they require special storage or handling conditions?

Size and complexity of your operations: How many locations, warehouses, or distribution centers do you have? How many suppliers and customers do you deal with? How much inventory do you need to keep on hand at each stage of the supply chain?

Level of demand and competition in your market: How predictable or volatile is your customer demand? How often do you need to replenish your stock? How do you balance the trade-off between stock availability and holding costs? How do you differentiate yourself from your competitors?

Goals and objectives of your business: What are your financial and operational targets? How do you measure your inventory performance and efficiency? How do you align your inventory strategy with your overall business strategy?

Tips for Effective Inventory Management

To make the most of your inventory management techniques, here are some tips that you can follow:

Set clear and realistic goals. For example, you can aim to reduce your inventory costs by 10%, increase your inventory turnover by 20%, or improve your customer satisfaction by 15%.

Review and update your inventory policies and procedures regularly For example, you can revise your reorder points, safety stock levels, or order quantities based on the changes in demand, supply, or market conditions.

Train and educate your staff on the importance and benefits of inventory management. You can educate employees on how inventory management affects the cash flow, profitability, and customer loyalty of your business.

Communicate and coordinate with your suppliers, customers, and other stakeholders. Share your inventory forecasts, orders, and feedback with your suppliers to ensure timely and accurate delivery. You can also inform your customers about your inventory availability, lead times, and delivery options to manage their expectations and satisfaction.

Measure and monitor your inventory performance and progress. Use key performance indicators (KPIs) such as inventory turnover ratio, days sales of inventory, gross margin return on investment, or fill rate to evaluate how well you are managing your inventory.

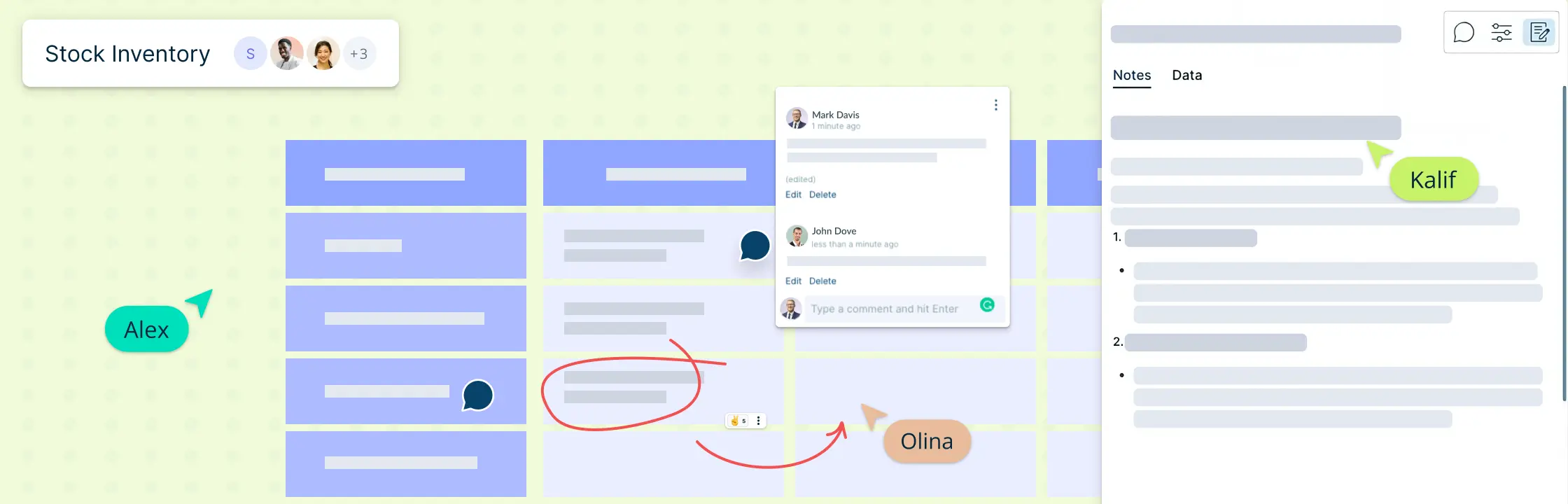

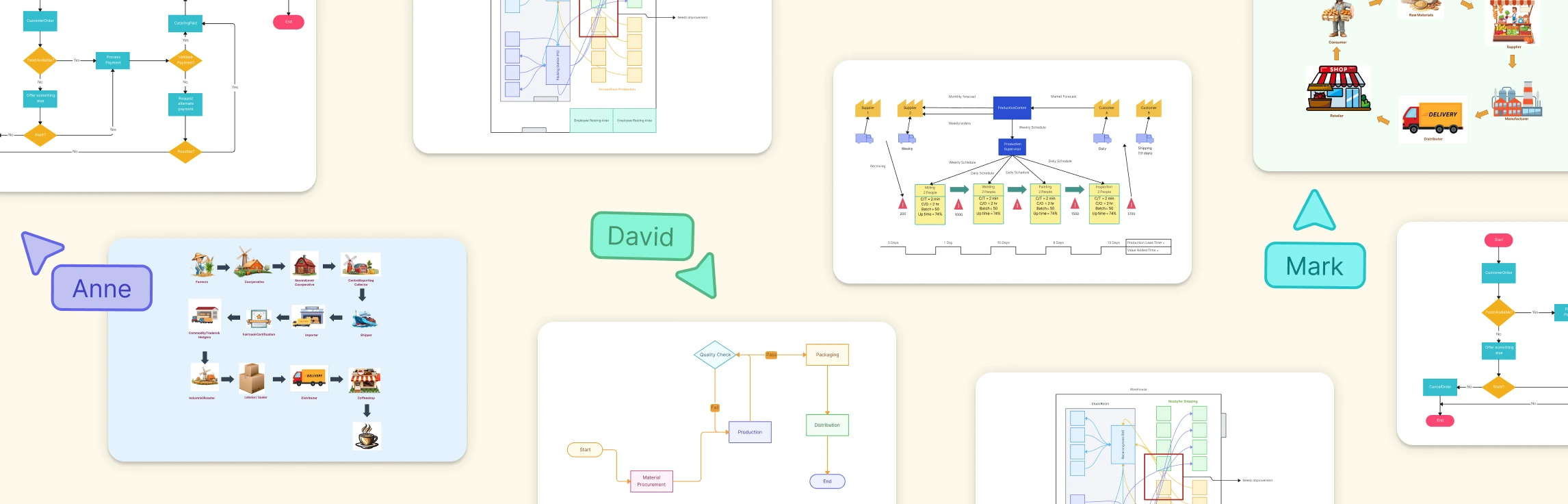

How Creately Helps You to Manage Inventory

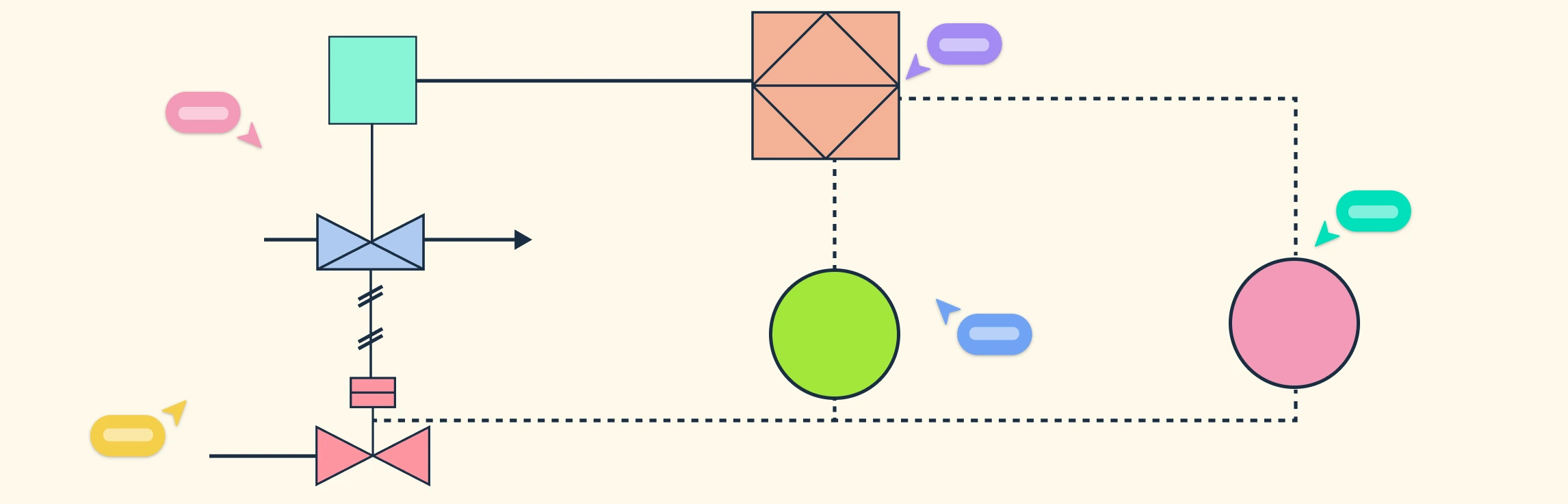

You can use Creately to design your inventory layout, track your stock levels and visualize processes to figure out inefficiencies.

Create and inventory layout. You can draw a layout from scratch by dragging and dropping shapes from the library or choose a customizable template. You can customize the shapes with colors, labels, and icons.

Connect the shapes with lines to show the flow of your inventory. You can use different line styles and arrows to indicate the direction and type of movement. ta panel. You can enter information such as item name, quantity, price, and barcode and any other necessary attachments.

Use the filters and search functions to find and highlight specific items in your inventory. You can also sort and group your items by different criteria.

Share your inventory diagram with others by exporting your diagram as an image or PDF, or embed it on your website or blog.

Wrapping Up

Inventory management is a vital aspect of any business that deals with goods or materials. By applying the inventory management techniques discussed in this post, you can optimize your inventory levels, reduce your inventory costs, increase your sales, improve your quality, and enhance your productivity.