In today’s dynamic business environment, fostering a culture of continuous improvement is essential for long-term success. The Kaizen methodology, with its roots in Japanese philosophy, emphasizes the power of small, incremental changes that drive significant improvements over time. Unlike traditional approaches that focus on large-scale transformations, Kaizen promotes steady, ongoing enhancements that build momentum gradually.

This guide explores the visual aspect of Kaizen methodology, showing how diagramming tools can simplify and amplify the process of driving continuous improvement. You’ll discover how to visualize Kaizen methodologies to streamline workflows, eliminate inefficiencies, and create a sustainable culture of innovation.

What Is Kaizen Methodology?

Kaizen methodology is centered on the practice of continuous improvement. The term “Kaizen” comes from the Japanese words “Kai” (meaning change) and “Zen” (meaning good), representing the idea of making good changes. After World War II, Kaizen gained prominence in Japanese businesses, particularly at Toyota, where it became an integral part of Lean manufacturing. This philosophy emphasizes the importance of ongoing, incremental improvements to enhance productivity, reduce waste, and add value.

What sets Kaizen apart is its focus on small-scale improvements that compound over time, rather than one-time, large-scale initiatives. Kaizen principles are not confined to specific projects or departments—it’s a company-wide effort where everyone, from the C-suite to the frontlines, is encouraged to identify opportunities for improvement and take part in implementing changes.

Key principles of Kaizen methodology include:

- Continuous improvement: Small, consistent changes lead to major long-term results.

- Employee involvement: Everyone in the organization, regardless of their role, contributes ideas and participates in the improvement process.

- Focus on small changes: Instead of radical overhauls, Kaizen targets small, manageable modifications that collectively enhance performance.

- Root cause analysis: Problems are addressed at their source, ensuring that solutions target the underlying issues, not just the symptoms.

This approach creates a culture of accountability, innovation, and efficiency throughout an organization.

The Key Elements of Kaizen

Successful implementation of the Kaizen methodology involves several key elements that work together to foster a culture of continuous improvement. These elements ensure that every individual and team is aligned with the goals of increasing efficiency, reducing waste, and enhancing overall performance.

1. Teamwork

At the heart of Kaizen is collaboration. Teamwork is crucial for identifying problems and generating innovative solutions. Kaizen fosters a culture where employees from different departments and levels come together, leveraging their unique perspectives and expertise. This collaborative approach enables diverse thinking, which leads to more creative and well-rounded solutions. Teamwork in Kaizen also ensures that improvements are not siloed but integrated across the organization, making changes more sustainable and impactful.

2. Personal Discipline

While teamwork is essential, Kaizen also places a strong emphasis on personal discipline. Employees are encouraged to take individual responsibility for their tasks and to actively seek out opportunities for self-improvement. Personal discipline in Kaizen means consistently adhering to established standards, being proactive about solving problems, and maintaining a high level of commitment to the process. This element empowers employees to be accountable for their actions, leading to a more engaged and motivated workforce.

3. Improved Morale

One of the key benefits of Kaizen is its positive impact on employee morale. By encouraging everyone to participate in the improvement process, Kaizen makes employees feel valued and respected. When workers see that their ideas and suggestions are being taken seriously and implemented, it boosts their sense of ownership and pride in their work. This increased job satisfaction leads to higher levels of motivation and engagement, which directly contributes to better overall performance and retention.

4. Quality Circles

Kaizen emphasizes the use of quality circles—small groups of employees who regularly meet to identify, analyze, and solve workplace challenges. These quality circles are a vital tool for continuous improvement because they empower employees to take an active role in shaping their work environment. By regularly meeting to discuss issues and propose solutions, employees gain a sense of empowerment and are more invested in the success of the organization. Quality circles also encourage open communication, enabling teams to share knowledge and best practices across the company.

5. Standardization

Another key element of Kaizen is the importance of standardizing successful improvements. Once a process has been optimized, it is essential to document and standardize the new practices so that they can be consistently applied across the organization. Standardization ensures that improvements are not lost over time and become part of the daily operations, forming a stable foundation for further enhancements.

6. Continuous Feedback and Evaluation

Kaizen is an iterative process, and continuous feedback is critical to its success. Regularly monitoring and evaluating the effectiveness of implemented changes allows organizations to quickly identify areas that require further improvement. By fostering a feedback loop, organizations can ensure that they remain agile, continuously refining their processes to meet evolving demands.

These key elements—teamwork, personal discipline, improved morale, quality circles, standardization, and continuous feedback—form the backbone of Kaizen methodology. Together, they create a dynamic system where both individuals and teams are empowered to contribute to the organization’s long-term success through continuous, incremental improvements.

Incorporating Diagramming into Kaizen Methodology

Using diagramming to represent Kaizen methodology can significantly enhance understanding and engagement by transforming abstract concepts into clear, visual frameworks. Here are some detailed ideas for incorporating different types of diagrams to communicate key aspects of Kaizen.

1. Kaizen Cycle Diagram (PDCA Cycle)

The PDCA (Plan-Do-Check-Act) cycle is at the heart of Kaizen’s approach to continuous improvement. Visualizing this cycle in a diagram allows readers to see how the methodology functions in ongoing, iterative loops.

- Plan: Outline the identification of issues and set objectives for improvement. This stage often involves data collection and analysis, making it a vital part of preparing for change.

- Do: Implement the change or solution on a small scale. The diagram can highlight pilot tests or trial phases before full-scale implementation.

- Check: Use metrics to evaluate the effectiveness of the changes. Visual representations can include data flow and performance metrics to demonstrate progress.

- Act: If the solution works, standardize it; if not, make adjustments and repeat the cycle. The diagram emphasizes that this is not a one-time process but a recurring effort.

This visual representation simplifies understanding of how Kaizen operates as a cycle of continuous improvement, ensuring readers grasp the importance of small, iterative changes over time.

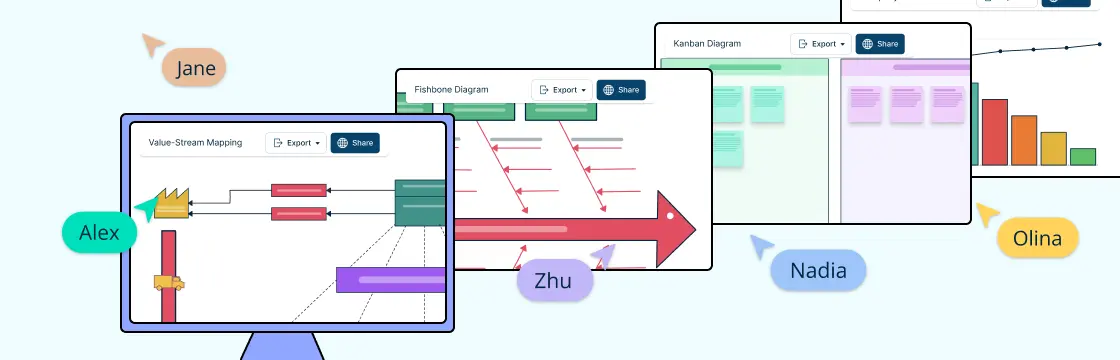

2. Value Stream Mapping

Value Stream Mapping (VSM) is a powerful tool used in Kaizen to visualize the flow of materials and information through a process, identifying inefficiencies and opportunities for improvement. By breaking down the entire process into distinct segments, value stream mapping tool helps organizations pinpoint areas where waste occurs and implement targeted changes.

1. Production or Process Flow

The first segment of a value stream map is the Production or Process Flow, which outlines the sequence of tasks involved in producing a product or delivering a service. This flow is drawn from left to right, similar to a traditional process flowchart.

- Main Tasks: The major steps that occur repeatedly throughout the process are highlighted prominently. These steps represent the core activities that add value to the product or service.

- Subtasks and Parallel Tasks: Any subtasks or parallel activities are drawn beneath the main flow. This structure helps differentiate between essential activities and supporting actions, making it easier to identify areas where inefficiencies, delays, or unnecessary repetitions may occur.

By visualizing the entire process in this way, teams can better understand how work progresses, which steps add value, and where waste might be present.

2. Information or Communication Flow

The second segment focuses on the Information or Communication Flow, which maps out the interactions and information exchanges within the value stream.

- Communication Channels: This part of the map shows both formal and informal communication between departments, teams, or individuals. Unlike the production flow, which moves in a structured direction, communication can flow in any direction and may occur at various stages of the process.

- Clarity of Information: By identifying how and when communication happens, teams can spot gaps or delays in information transfer. This visibility allows organizations to streamline communication channels and reduce miscommunication, which is a common cause of inefficiency.

Including this flow in the value stream map ensures that the exchange of critical information is accounted for and optimized to support smoother operations.

3. Timelines and Travel Distances

The third segment of a value stream map deals with Timelines and Travel Distances, providing a clear view of the time and movement involved in the process.

- Process Lead Time: At the bottom of the map, the first timeline represents the process lead time, showing how long it takes to complete the entire workflow from start to finish.

- Cycle Time: The second timeline tracks the cycle time, which measures the actual time spent working on a product or task. Some maps may display labor content instead of cycle time, in which case it is referred to as Total Work Content.

- Travel Distances: Another line may illustrate the distance traveled, whether it’s the movement of materials, products, or even people within the process. Tracking travel distances helps identify excessive movement, which can contribute to wasted time and resources.

These time-related insights are critical in identifying bottlenecks, improving workflow efficiency, and reducing unnecessary delays in the value stream.

By breaking down processes into these segments, Value Stream Mapping allows organizations to not only visualize workflows but also to identify specific areas where Kaizen-driven improvements can have the most significant impact. This tool empowers teams to streamline processes, reduce waste, and continuously improve performance.

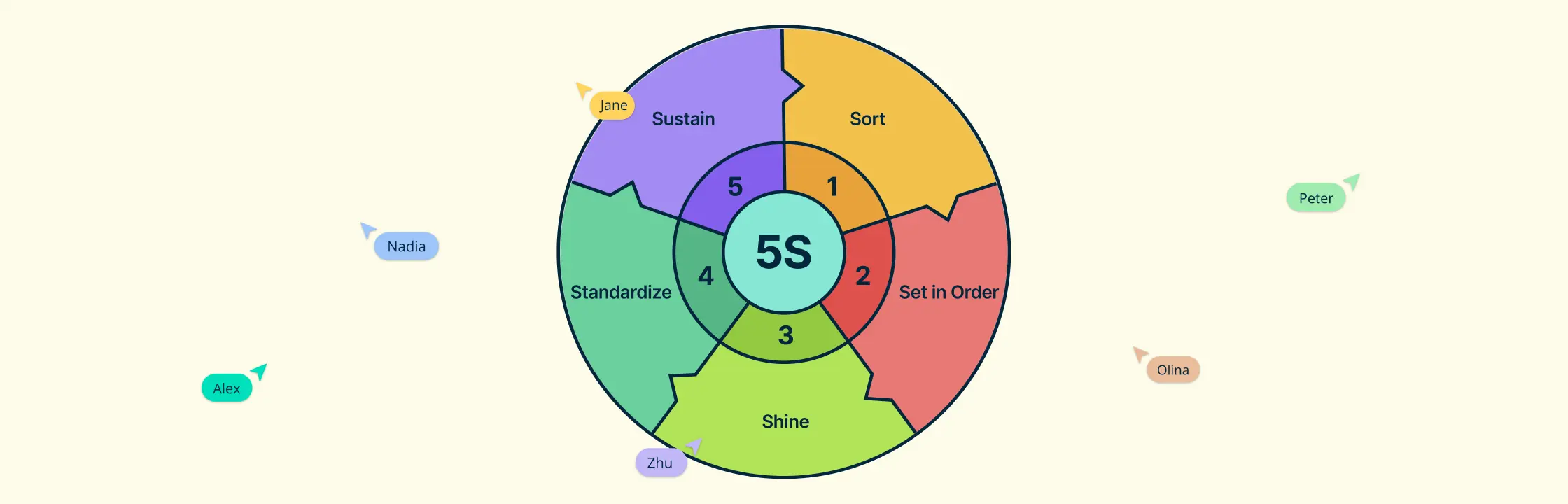

3. 5S Diagram

The 5S methodology (Sort, Set in Order, Shine, Standardize, Sustain) is an essential component of Kaizen. A visual representation of the 5S steps in a segmented circular diagram can make the concept more intuitive.

- Sort: Show examples of cluttered versus organized workspaces to emphasize the importance of eliminating unnecessary items.

- Set in Order: Illustrate efficient workspace arrangements with tools and materials placed for easy access, demonstrating the importance of logical layouts.

- Shine: Visuals of clean, well-maintained work areas can show how cleanliness contributes to productivity and safety.

- Standardize: Include standard operating procedures and visual work instructions to represent this step.

- Sustain: Highlight continuous efforts to maintain these improvements through regular audits and employee involvement.

By offering visual examples before and after 5S implementation, the diagram makes the Kaizen-driven transformation more tangible.

4. Fishbone Diagram (Ishikawa)

The Fishbone Diagram, also known as the Ishikawa or cause-and-effect diagram, is widely used in Kaizen for root cause analysis. It helps teams systematically break down potential causes of problems into categories, making complex issues easier to address.

- Categories: Represent common problem areas such as methods, materials, machines, people, environment, and management in the fishbone diagram’s “bones.”

- Root Cause Analysis: Demonstrate how problems can be traced to their root causes, rather than just addressing symptoms, by visually organizing factors that lead to issues.

- Actionable Solutions: Show how teams can use the diagram to identify areas where small changes can lead to significant improvements.

The fishbone diagram templates allow teams to systematically approach problem-solving in Kaizen, making it easier to identify causes and propose solutions.

5. Kanban Board

A Kanban Board is a powerful visual tool that complements Kaizen by helping teams track progress on tasks and manage workflow efficiently. Diagramming a Kanban board shows how tasks move through different stages of completion.

- Stages: Illustrate stages such as “To Do,” “In Progress,” “In Review,” and “Completed,” providing a clear overview of where work stands at any given moment.

- Work in Progress (WIP) Limits: Highlight the importance of limiting WIP to avoid bottlenecks, ensuring that teams focus on completing tasks before taking on new ones.

- Visual Cues: Use color coding or priority flags to show task urgency, helping teams prioritize their efforts more effectively.

This type of diagram can help teams visualize their workflow, track improvements, and ensure that work progresses smoothly within the Kaizen framework.

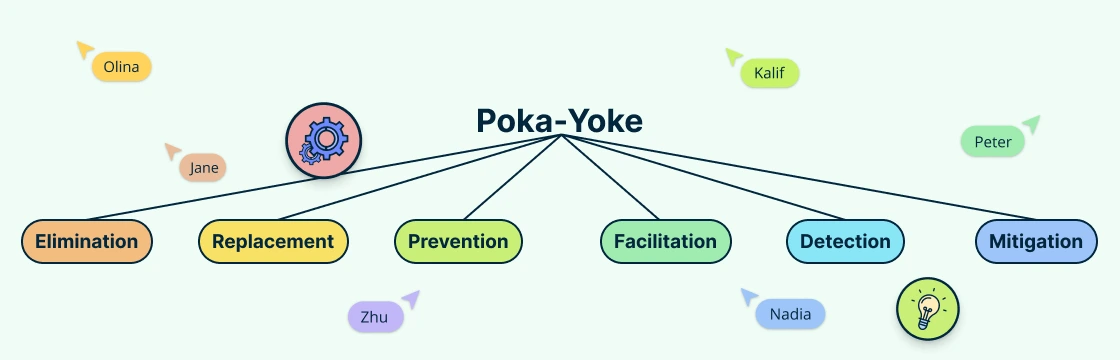

6. 5 Whys Analysis

The 5 Whys Analysis is an essential tool in the Kaizen methodology for identifying the root cause of problems and driving continuous improvement. By incorporating the 5 Whys diagram, teams can visually map out the cause-and-effect relationship of recurring issues, ensuring that they tackle the core problem rather than just treating symptoms.

- Problem Identification: As part of a Kaizen event or regular improvement cycle, teams can start by identifying a problem area that needs improvement. The 5 Whys process helps uncover underlying issues hindering productivity or quality.

- Visualizing the Process: In the diagram, each “Why” asked reveals a deeper cause, which helps teams explore incremental improvement opportunities. The diagram visually traces these back to the root cause, making it easier to see connections and pinpoint where Kaizen principles can be applied.

- Driving Action: Once the root cause is identified, the diagram can lead to concrete action steps, encouraging small, manageable changes to address the issue, which aligns with Kaizen’s principle of continuous, incremental improvement.

This analysis helps to identify the root cause of an issue by going through each level of the problem while the visual breakdown helps the team implement targeted Kaizen strategies.

7. Gemba Walk Diagram

Gemba Walks are a foundational practice in Kaizen, focusing on the importance of observing real work processes on the shop floor. Incorporating a Gemba Walk Diagram into Kaizen methodology allows managers and leaders to structure their observations and effectively identify areas of waste, inefficiency, or improvement opportunities.

- Observation of Processes: The diagram visually outlines the steps in a work process that managers should observe during a Gemba Walk, aligned with Kaizen’s focus on hands-on understanding of the actual work environment (the “Gemba”).

- Identifying Waste: The diagram helps visualize points of inefficiency or waste (e.g., delays, excess movement, or bottlenecks) that managers can focus on during the walk. These insights are critical for Kaizen’s emphasis on waste reduction.

- Employee Engagement: It maps out key interaction points where managers can ask employees for insights or suggestions. This ensures that continuous improvement is informed by those who are directly involved in the work, reflecting Kaizen’s principle of involving all employees.

This framework encourages observation of the actual workflow, engaging with employees, making it easier to implement a collaborative approach to problem-solving and improvement.

Enhancing Continuous Improvement with Visual Tools in Kaizen

Incorporating diagramming into the Kaizen methodology amplifies the impact of continuous improvement by making the process more transparent, structured, and engaging. Visual tools such as the PDCA cycle, Value Stream Mapping, 5 Whys Diagram, and Gemba Walk Diagram help teams identify inefficiencies, track progress, and develop actionable solutions. These diagrams not only simplify complex processes but also foster collaboration by allowing everyone—from management to frontline employees—to contribute to the improvement process.

By combining the Kaizen philosophy with powerful visual aids, organizations can achieve more sustainable and meaningful improvements. Whether it’s eliminating waste, enhancing productivity, or boosting employee morale, these diagrams bring the Kaizen methodology to life, driving both incremental and transformative changes across industries.