Every system, no matter how meticulously designed, carries the risk of failure. When the stakes are high—be it in aerospace, manufacturing, or software engineering—understanding potential vulnerabilities becomes critical. Fault Tree Analysis (FTA) provides a structured way to dissect these risks, empowering professionals to uncover hidden weak points and prevent disasters before they occur. With its graphical approach, FTA turns complex interdependencies into clear, actionable insights.

This article explores the methodology, tools, and applications of FTA, offering a closer look at how it enables industries to enhance safety and reliability. Whether you’re a safety engineer, quality assurance professional, or project manager, mastering this technique could be the key to designing more robust systems and reducing operational risks. Dive in to discover how FTA transforms intricate failure scenarios into manageable pathways toward solutions, making risk management a collaborative and informed process.

What is a Fault Tree Analysis?

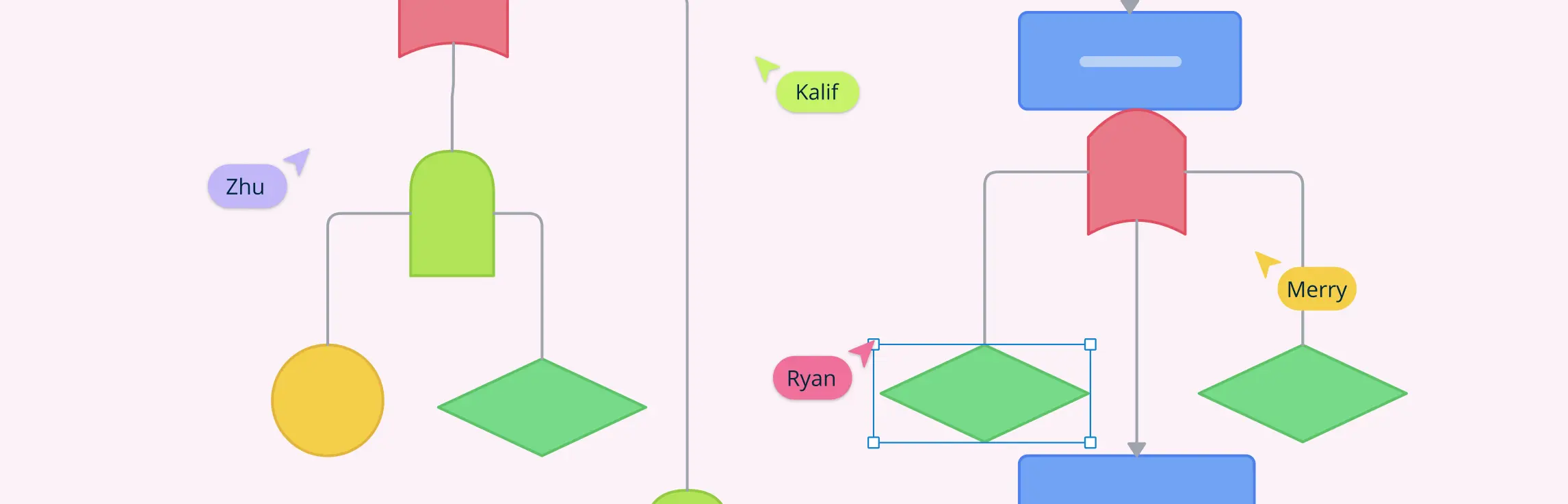

Fault Tree Analys is (FTA) is a top-down, graphical method used to determine the causes of system failures, making it an invaluable asset in high-risk industries. Engineers and project managers frequently utilize FTA to enhance system reliability and safety by visualizing potential failure pathways. This detailed analysis enables stakeholders to understand complex interdependencies and collaboratively address potential issues. The visual nature of a Fault Tree Analysis Diagram aids in transparent communication, facilitating discussion and collaborative problem-solving across teams.

Fault Tree Analysis (FTA) represents a powerful tool for dissecting and understanding potential system failures, especially within complex systems. This analysis technique uses a visualization known as a Fault Tree Analysis Diagram, which helps identify the interdependencies between different fault events. FTA breaks down an undesirable event, or “top event,” into its component causes, often using logical gates to map these interactions. This method is a top-down approach aimed at identifying causes and sub-causes to prevent system breakdowns.

Key Features of Fault Tree Analysis

Fault Tree Analysis (FTA) serves as an invaluable tool for systematically examining system vulnerabilities and predicting system failures. Several features distinguish FTA from other reliability techniques, making it a preferred choice among engineers and quality assurance teams.

Top-Down Approach

FTA employs a methodical top-down approach, starting from a primary failure (often called the Top Event) and dissecting it into its underlying causes and contributing factors. This breakdown enables organizations to clearly identify the root causes of failures, facilitating targeted mitigation strategies. Such an approach is particularly beneficial in industries like aerospace and nuclear energy, where understanding the chain of faults can prevent catastrophic outcomes.

Use of Logic Gates

The use of logic gates in FTA diagrams provides an illustrative way to depict the relationships between different faults and errors. Logic gates such as AND, OR, and others highlight how events within a system interact and lead to system-wide failures. These logic gates play a crucial role in visually representing the simultaneous and sequential interactions between different sub-events in the system.

Focus on Safety and Reliability

As a tool, FTA emphasizes enhancing the reliability and safety of complex systems. By pinpointing weak links in the system, FTA supports the design of safer, more resilient infrastructures, playing a critical role in industries where safety is paramount. From advising on preventive maintenance schedules to suggesting design modifications, FTA is integral in ensuring systems’ operational integrity.

Identification of Weak Points

A vital feature of fault tree analysis is its ability to spotlight systemic weak points. By revealing these vulnerabilities, FTA enables organizations to prioritize improvements strategically, reducing the likelihood of failures. This targeted focus helps in optimizing resources for maximum safety impact, making FTA an efficient risk management tool.

Through Creately’s intuitive platform, FTA can be augmented by visual aids that allow teams to collaboratively build fault tree diagrams. This promotes a more comprehensive understanding and quicker resolution of issues — key for ongoing safety and reliability improvements.

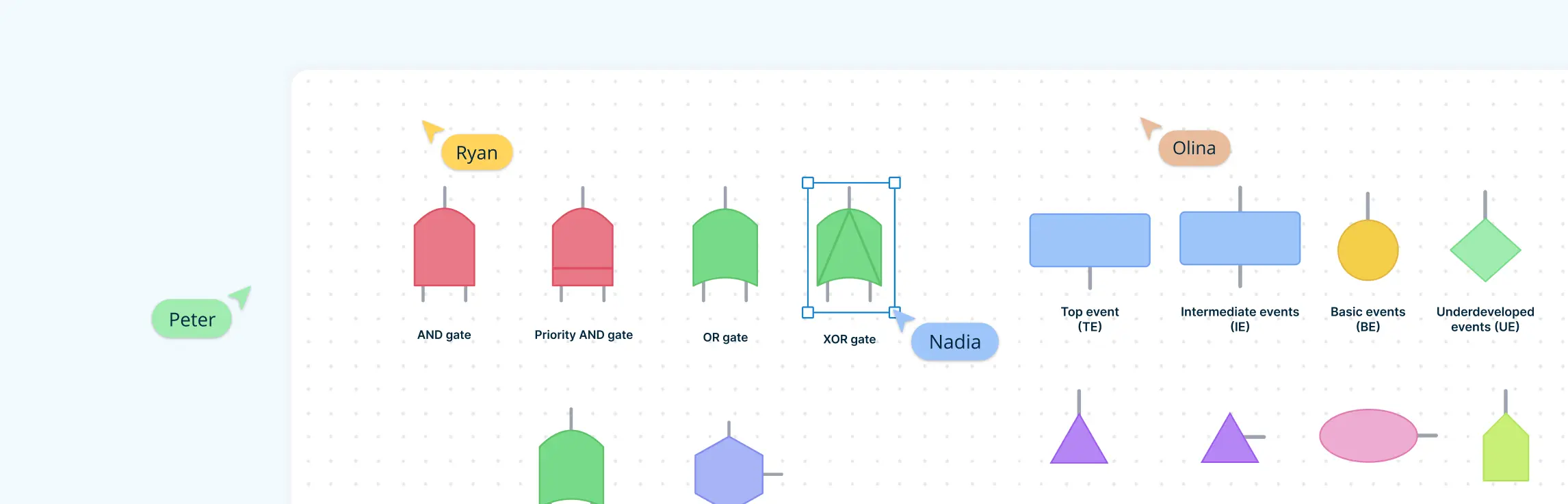

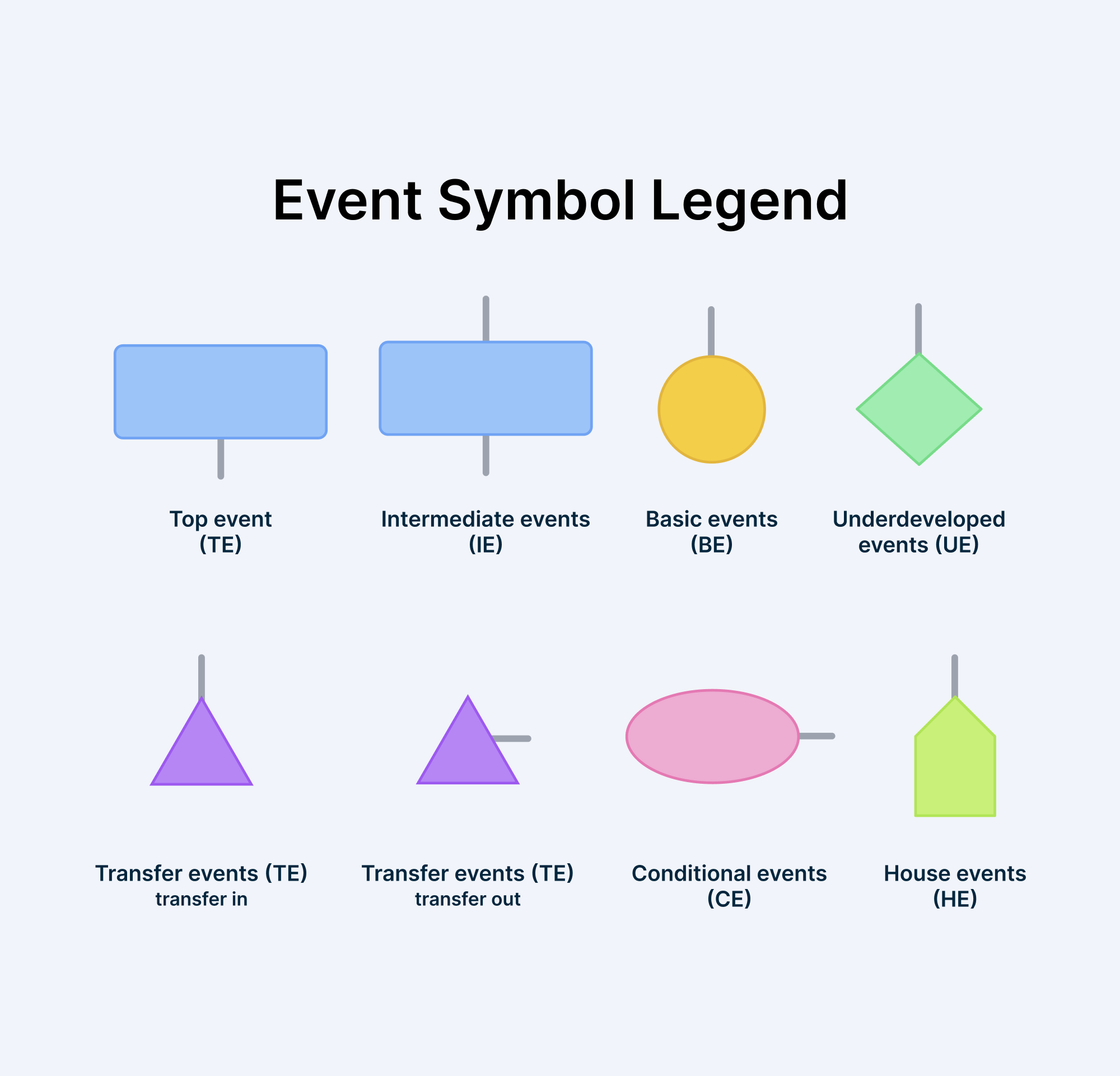

In the realm of fault tree analysis (FTA), understanding the core symbols used is crucial as they form the backbone of a fault tree diagram. These symbols are categorized into Event Symbols and Gate Symbols, each playing a distinct role in portraying various failure types and their logical relationships.

Who Uses a Fault Tree Analysis

Fault Tree Analysis is utilized by various professionals and teams across different organizational levels:

Safety Engineers: These specialists use FTA as a primary tool for conducting comprehensive safety assessments and developing preventive measures in high-risk environments.

Quality Assurance Teams: QA professionals employ FTA to identify potential quality issues in products and processes before they occur, ensuring consistent product reliability.

Risk Management Professionals: Risk managers use FTA to evaluate potential system vulnerabilities and develop mitigation strategies to protect organizational assets.

System Design Engineers: During the design phase of complex systems, engineers utilize FTA to identify and eliminate potential failure points before implementation.

Maintenance Teams: Maintenance personnel use FTA to understand failure patterns and develop more effective preventive maintenance schedules.

Project Managers: In complex projects, managers use FTA to identify potential failure points that could impact project timelines and deliverables.

Operations Managers: These professionals use FTA to optimize operational processes and prevent costly downtimes in production environments.

Compliance Officers: In regulated industries, compliance teams use FTA to ensure systems meet safety and reliability standards required by regulatory bodies.

Understanding The Symbols of Fault Tree Analysis

Event Symbols

Event Symbols depict different stages or aspects of a failure within the system. Each symbol type captures unique details and context about failure events, facilitating targeted analyses. Here’s a breakdown:

Top Event (TE): This event is situated at the top of the fault tree, triggering the entire investigation as it represents the system failure or undesired outcome.

Intermediate Events (IE): These are caused by one or more events and can lead to subsequent system failures.

Basic Events (BE): These sit at the bottom of the tree, indicating root causes with no further breakdown.

Underdeveloped Events (UE): Events with insufficient detail for a detailed investigation, placed as subtrees.

Transfer Events: Used when a fault tree is too extensive, marking sections that expand into separate trees. Transfer-in and Transfer-out types depict flow direction.

Conditional Events (CE): They act as conditions required for certain logical gates, specifically the INHIBIT gate, to function.

House Events (HE): These symbols modulate event inclusion within fault tree analysis, toggling system portions on or off.

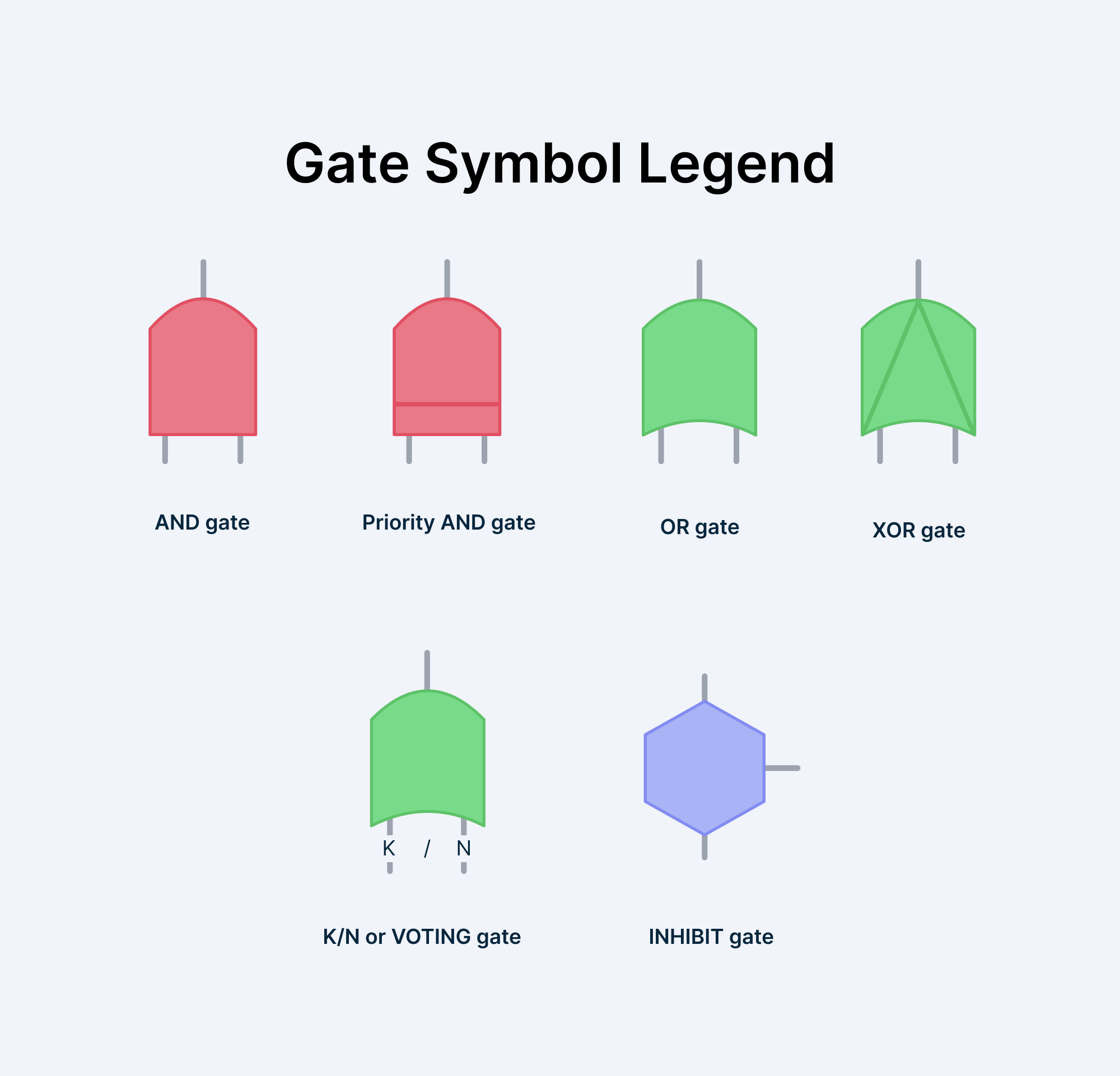

Gate Symbols

Gate Symbols illustrate how multiple events culminate into a failure, highlighting the intricate web of interdependencies between them.

Gate Symbols illustrate how multiple events culminate into a failure, highlighting the intricate web of interdependencies between them.

AND Gate: A critical condition where all input events must occur for the output failure event to proceed.

OR Gate: Conversely, only one of the input events needs happening to trigger the specified failure outcome.

Priority AND Gate: This requires input events to occur in a particular sequence.

XOR Gate: An output event happens only if one, and not all, input events occur, reflecting unique causation dynamics.

k/N or Voting OR Gate: This indicates an output event if a specific number of occurrences among possible input events take place.

INHIBIT Gate: Requires all input conditions plus a specified condition to fulfill the fault condition.

The understanding and application of these symbols enable clearer and more effective fault tree analyses, facilitating system reliability and safety assessments across industries. These diagrams are essential not only for systemic evaluation but for proactive design enhancements, making tools like Creately invaluable for visualizing and collaborating on complex fault tree symbols.

Performing a Fault Tree Analysis (FTA) is a meticulous process aimed at dissecting system failures to prevent future occurrences. Here’s a step-by-step guide to conducting an effective FTA:

Helpful Resources

A systematic problem-solving method that helps identify the underlying source of issues rather than just addressing symptoms. Includes techniques like 5 Whys and Fishbone Diagrams.

Strategic frameworks and methods to evaluate options and make informed choices, including decision matrices, cost-benefit analysis, and weighted scoring models.

Comprehensive overview of Six Sigma methodology tools including DMAIC process, control charts, process capability analysis, and statistical quality control methods.

Steps to Conduct a Fault Tree Analysis

1. Define the Top Event

The first and most crucial step in conducting a Fault Tree Analysis is precisely defining the top event. This undesired outcome serves as the focal point of your entire analysis and must be specific, measurable, and clearly understood by all stakeholders. A well-defined top event allows teams to maintain focus and ensures that the subsequent analysis effectively addresses the core issue at hand.

Clearly articulate the specific failure or undesired event to be analyzed

Define temporal aspects (when does the failure occur?)

Specify the operational state during failure

Document all relevant system conditions and parameters

Set clear boundaries for what is and isn’t included in the analysis

Create a precise problem statement that all stakeholders agree upon

Example: “Complete production line stoppage lasting more than 30 minutes during normal operation”

2. Understand the System

Before diving into the construction of the fault tree, it’s essential to develop a comprehensive understanding of the system under analysis. This understanding forms the foundation for identifying potential failure modes and their interactions. Teams should invest significant time in this phase, as incomplete system knowledge can lead to overlooked failure pathways and ineffective analysis.

System Documentation Review

Collect and review all technical specifications

Study system design documents and drawings

Examine operating procedures and manuals

Review maintenance records and history

Gather performance data and metrics

Analyze previous failure reports and incidents

Stakeholder Engagement

Interview system operators and maintenance personnel

Consult with system designers and engineers

Engage with quality control teams

Speak with production supervisors

Document tribal knowledge and experience

Capture historical insights and lessons learned

Environmental Factors

Identify operating conditions and constraints

Document environmental influences

List external dependencies

Note seasonal or cyclical factors

Consider regulatory requirements

Map system interfaces and boundaries

3. Construct the Fault Tree Diagram

The construction phase transforms your system understanding into a visual representation of failure pathways. This process requires methodical thinking and attention to detail, as the diagram will serve as the primary tool for analysis and communication. The fault tree should be built systematically, ensuring that each branch accurately represents the logical relationship between events.

Structural Elements

Place the top event at the apex of the tree

Break down into intermediate events using appropriate symbols

Connect events using logical gates

Ensure consistent level of detail across branches

Use standardized symbols and nomenclature

Maintain clear and logical flow

Logic Gate Implementation

The proper use of logic gates is crucial for accurately representing how different events combine to cause failures. Each gate type serves a specific purpose and should be selected carefully to reflect the true relationship between events.

AND Gates

Used when all input events must occur for output

Represents redundancy in system design

Common in safety-critical systems

Example: “Both primary and backup power must fail”

OR Gates

Used when any input event causes output

Represents system vulnerabilities

Common in single-point failures

Example: “Either material shortage or equipment failure causes stoppage”

Advanced Gates

PRIORITY AND: Events must occur in specific sequence

INHIBIT: Conditional event must be present

EXCLUSIVE OR: Exactly one input must occur

VOTING: K-out-of-N events must occur

4. Analyze the Fault Tree

Analysis transforms the fault tree from a descriptive tool into an actionable source of insights. This phase combines qualitative and quantitative techniques to identify critical failure pathways and prioritize risk mitigation efforts. The analysis should be systematic and documented thoroughly to support decision-making.

Qualitative Analysis

The qualitative phase focuses on understanding failure mechanisms and their relationships without necessarily quantifying probabilities.

Identify all possible failure pathways

Determine minimal cut sets

Evaluate common cause failures

Assess system vulnerabilities

Review redundancy effectiveness

Map failure propagation paths

Quantitative Analysis

When data is available, quantitative analysis provides numerical insights into system reliability and risk.

Calculate failure probabilities

Determine component reliability

Assess system availability

Compute importance measures

Evaluate uncertainty ranges

Model failure distributions

5. Mitigate Risks

Risk mitigation transforms analytical insights into practical actions that improve system reliability and safety. This phase requires careful prioritization and resource allocation to address the most critical risks effectively while considering implementation constraints.

Strategy Development

Prioritize risks based on analysis results

Develop multiple mitigation options

Evaluate cost-benefit ratios

Consider implementation feasibility

Assess potential secondary effects

Create action timelines

Implementation Planning

Assign responsibility for actions

Allocate necessary resources

Define success criteria

Establish monitoring mechanisms

Create contingency plans

Set review milestones

Verification and Follow-up

Continuous monitoring and adjustment ensure the effectiveness of implemented solutions and capture opportunities for improvement.

Test and validate solutions

Monitor performance metrics

Document effectiveness

Update analysis as needed

Schedule periodic reviews

Maintain change records

Fault Tree Analysis Examples: Real-World Applications

Fault Tree Analysis (FTA) has found its place among several high-stakes industries due to its precision in identifying and mitigating failures. Let’s look at three real-world applications where FTA plays a crucial role:

Aerospace: In the aerospace sector, reliability and safety of critical systems such as engine controls are non-negotiable. FTA helps to ensure that potential risks are identified and addressed effectively, minimizing the chance of catastrophic failures. Engineers can simulate different failure scenarios and develop robust preventive measures, thus securing safety and improving performance.

Manufacturing: Manufacturing environments often face potential process halts. Here, FTA is instrumental in detecting vulnerabilities in machinery and processes (for efficiently streamlining operations). By systematically analyzing failures, FTA aids manufacturers in pinpointing root causes that could disrupt operations, hence facilitating continuous smooth functioning. This proactive approach leads to better incident management and optimal system design.

Software Engineering: In the complex realm of software development, FTA is valuable for debugging intricate systems. Through a top-down analysis of software architectures, engineers can trace operational failures back to their origins, facilitating fast and effective troubleshooting. This methodology not only aids in addressing systemic software failures but also enhances strategic IT planning.

Advantages Of Fault Tree Analysis

Fault Tree Analysis (FTA) offers organizations a multitude of advantages, making it an indispensable tool in the realm of system reliability and risk management. Here are the key benefits that set FTA apart from other analytical methods:

Visual Representation: One of the defining strengths of FTA is its ability to visually represent complex systems and their failure pathways. By employing diagrams and symbols such as events and logic gates, FTA simplifies the understanding of how different failure modes interact, providing a clear visual trail from cause to consequence.

Root Cause Identification: FTA enables a systematic approach to identifying the root causes of failure. By starting with a top event and systematically working down to basic events, organizations can uncover hidden vulnerabilities within their systems, addressing core issues as opposed to only tackling symptoms.

Enhanced Risk Management: FTA supports both qualitative and quantitative analysis, which aids in the calculation of failure probabilities. This dual-approach allows organizations to prioritize risks effectively by focusing on those with the highest likelihood of occurrence and impact, facilitating informed decision-making.

Regulatory Compliance and Safety Assurance: By aligning with industry safety regulations, FTA ensures compliance by systematically assessing risks and identifying necessary improvements. This is crucial in high-stakes sectors such as aerospace, nuclear power, and chemical processing, where safety is paramount.

Cross-Disciplinary Collaboration: The structured nature of FTA fosters collaboration across different disciplines within an organization. By involving diverse teams in the analysis process, it encourages various perspectives, leading to more comprehensive risk assessments and solution strategies.

Prioritization of System Design Improvements: FTA allows organizations to pinpoint which failures are most likely and critical, thus highlighting areas where design changes are most needed. This strategic approach drives enhancements in system design, contributing to overall robustness and reliability.

Disadvantages of Fault Tree Analysis

While Fault Tree Analysis (FTA) is a powerful tool for system reliability and risk assessment, it is not without its limitations. Understanding these challenges is crucial for organizations to apply FTA effectively and mitigate potential shortcomings.

Complexity with Large Systems

Fault Tree Analysis can become significantly complicated when applied to large, intricate systems. As the number of components and interactions increases, the analysis becomes increasingly challenging to manage and comprehend.

Organizations often encounter overwhelming visual representations, experience exponential growth of fault tree complexity, and face increased difficulty in maintaining comprehensive coverage. The substantial resource investment required for detailed analysis heightens the likelihood of overlooking critical failure modes, making the process both time-consuming and potentially incomplete.

Assumption of Independence

The traditional FTA methodology operates under the assumption that system events are independent of each other. This fundamental limitation can lead to significant misrepresentations of real-world system behaviors.

Such assumptions can result in critical issues, including oversimplification of complex system interactions, potential underestimation of failure probabilities, and failure to capture interconnected failure mechanisms. The approach often reduces the accuracy of risk assessment and misrepresents systemic vulnerabilities, potentially creating a false sense of system reliability.

Requires Specialized Expertise

Conducting an effective Fault Tree Analysis demands a high level of technical knowledge and specialized skills. The complexity of the method requires deep understanding and extensive experience.

The expertise challenges are profound and multifaceted. Professionals must possess a comprehensive system understanding, ability to identify all relevant failure modes, and skill in constructing accurate and detailed fault trees. The method requires cross-disciplinary technical knowledge, and there’s an inherent potential for human error and subjective interpretation. This necessitates teams with advanced technical backgrounds and significant analytical capabilities.

Limited Scope of Analysis

Fault Tree Analysis typically focuses on a single top event at a time, which can create significant limitations in comprehensive system reliability assessment. This approach necessitates multiple, sequential analyses to cover various potential failure scenarios.

The limitations manifest in several critical ways: creating a fragmented view of system reliability, becoming a resource-intensive process, requiring comprehensive and sequential evaluations, and making it difficult to capture holistic system performance. The time-consuming nature of thorough investigations can potentially slow down decision-making processes and system improvements.

Leveraging Creately for Fault Tree Analysis

Digital Transformation of Traditional FTA

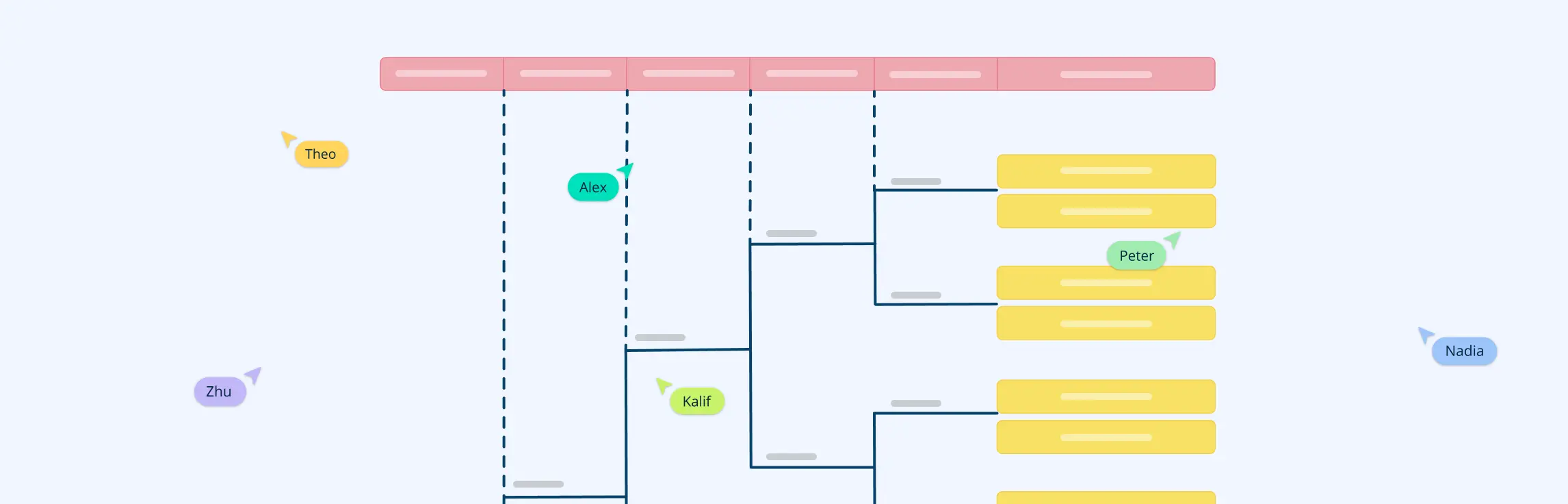

Creately revolutionizes the traditional Fault Tree Analysis process by transforming it into a dynamic, collaborative digital experience. Unlike conventional diagramming tools, the platform provides a specialized environment that streamlines every phase of FTA, from initial planning through to implementation and monitoring.

Key Collaborative Features:

Real-time multi-user editing with live cursor tracking

In-context commenting and discussion threads

Version history and change tracking

Role-based access control

Automated sync across devices and platforms

Creating live documents that are always updated

Sharing formats and features

Advanced Visualization and Diagramming

The platform’s visualization capabilities enable teams to create clear, professional fault tree diagrams that enhance understanding and facilitate modification. Creately’s intuitive interface combines powerful diagramming tools with specialized FTA elements to support even the most complex analyses.

Diagramming Tools:

Comprehensive library of standardized FTA symbols

Smart connectors that are context-aware

Drag-and-drop functionality

Customizable templates for different industries

Color coding and visual hierarchy options

Multiple export formats (PDF, PNG, SVG)

Team Collaboration and Analysis

Creately transforms FTA into a truly collaborative process by providing tools that facilitate team-based analysis and decision-making. The platform enables seamless communication and knowledge sharing across departments and locations, ensuring all stakeholders can contribute effectively to the analysis.

Collaboration Features:

Shared workspaces for cross-functional teams

Task assignment and tracking

Searchable comments and discussions

Fault Tree Analysis (FTA) stands as a cornerstone methodology for analyzing and mitigating system failures. Its structured, top-down approach not only identifies the root causes of issues but also fosters collaboration across teams, ensuring that safety and reliability remain at the forefront of operations. By leveraging FTA, organizations gain deeper insights into their systems, enabling them to address vulnerabilities proactively and design more resilient infrastructures.

Incorporating modern tools like Creately further enhances the FTA process, making it more collaborative, efficient, and visually engaging. These advancements help bridge the gap between technical analysis and team understanding, streamlining decision-making and fostering innovation.

Are you interested in exploring different failure analysis methods? Check out the FMEA Analysis Template and our Decision Tree Analysis Template for comprehensive resources.

Sources

“What Is a Fault Tree Analysis? IBM.” www.ibm.com, 2024, www.ibm.com/topics/fault-tree-analysis.

“What Is Fault Tree Analysis and How to Perform It” Limble, 13 May 2021, www.limblecmms.com/blog/fault-tree-analysis/.